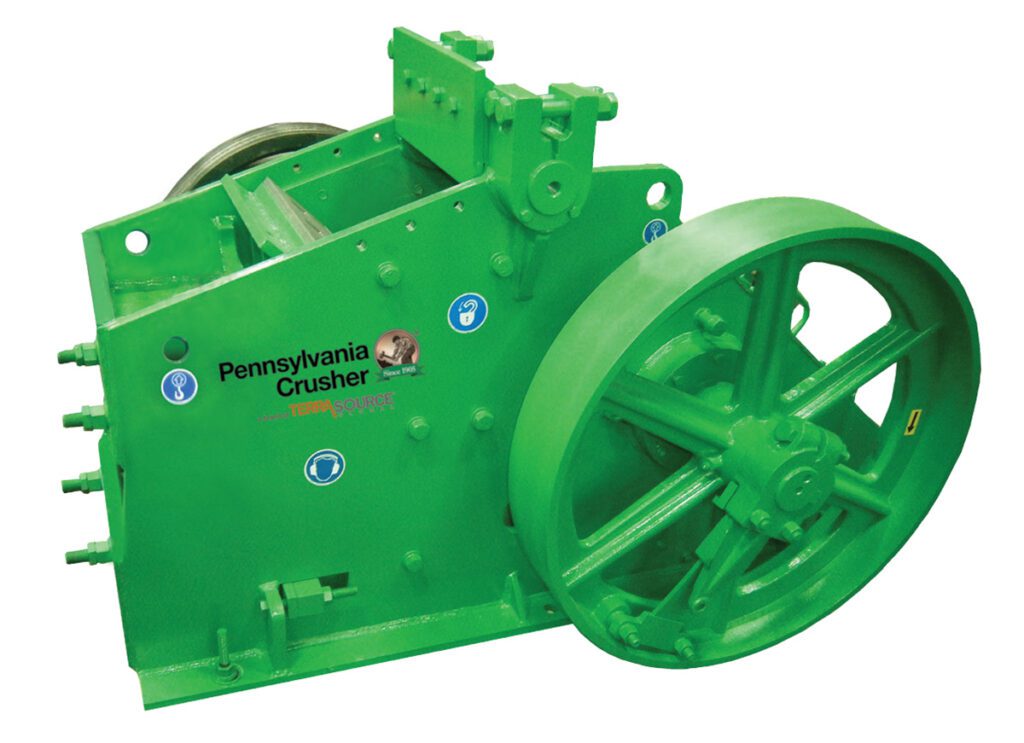

Jaw Crushers

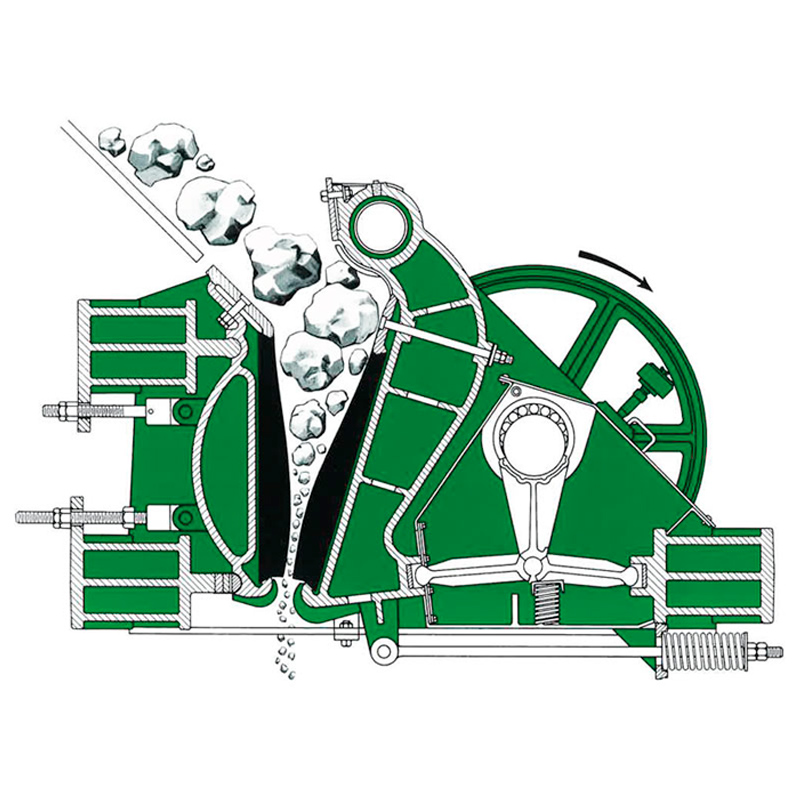

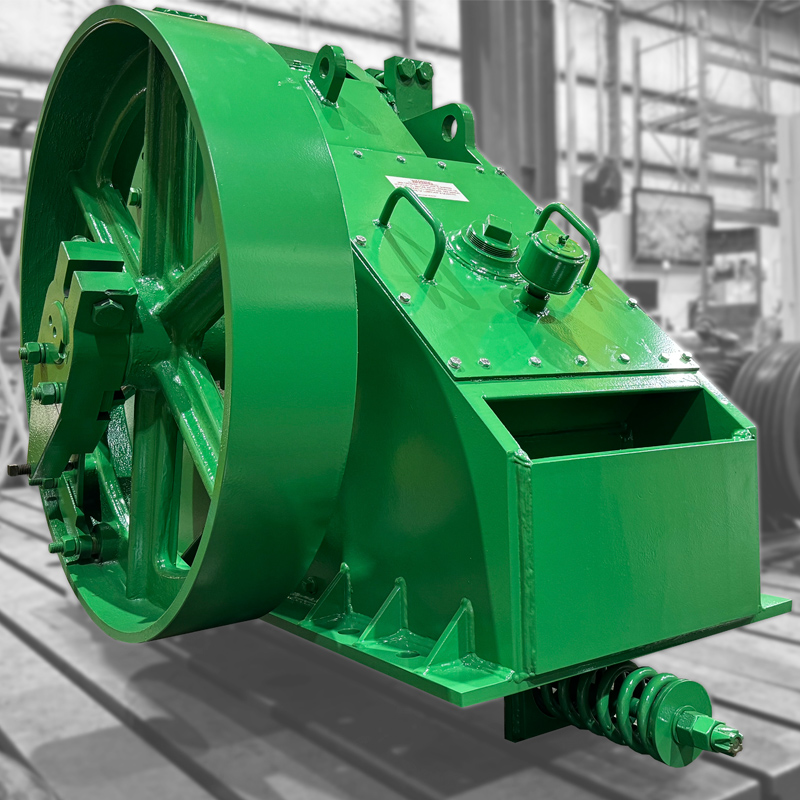

Pennsylvania Crusher’s Jaw Crushers stand out in the world of crushing equipment with their unique double toggle design. Unlike other crushers, they operate by compressing materials between two opposing surfaces, resulting in longer jaw service life, minimal dusting, and reduced wear and tear. These crushers are particularly favored by the glass industry, where they excel at crushing cullet into the desired particle size while preventing glass from escaping undamaged. Additionally, they offer enclosed lubrication and a tramp protection mechanism for added safety. Beyond glass, Pennsylvania Crusher’s double toggle jaw crushers are also a top choice for primary metal industries, effectively reducing abrasive ferroalloy additives with their compression-based approach, delivering superior performance without the need for heavy foundations.

Features

- Efficient Compression Crushing: Crushes materials efficiently between opposing surfaces for effective crushing.

- Versatility: Available in Double Toggle and Overhead Eccentric models for diverse crushing needs.

- Cullet Crushing: Specifically designed for the glass industry to crush cullet into desired sizes.

- Extended Service Life: Strict compression design extends jaw service life.

- Minimal Dusting: Reduced dust generation for employee and equipment safety.

- Enclosed Lubrication: Protected lubrication system ensures smooth operation.

- Tramp Protection: Safety mechanism protects crusher and motor from damage.

- Efficient Design: Strong top crushing stroke reduces abrasion and gouging.

- Low Fines Production: Minimizes fine particle generation for efficient crushing.

- Minimal Foundation Requirements: Balanced moving parts reduce foundation costs.

- Wide Range of Applications: Suitable for tough materials like rock and ferroalloys.

- Strength and Durability: Superior compressive crushing action ensures durability.

- Primary Metal Industries: Accepted in primary metal industries for high-strength materials.

- Efficient Compression Crushing: Crushes materials efficiently between opposing surfaces for effective crushing.

- Versatility: Available in Double Toggle and Overhead Eccentric models for diverse crushing needs.

- Cullet Crushing: Specifically designed for the glass industry to crush cullet into desired sizes.

- Extended Service Life: Strict compression design extends jaw service life.

- Minimal Dusting: Reduced dust generation for employee and equipment safety.

- Enclosed Lubrication: Protected lubrication system ensures smooth operation.

- Tramp Protection: Safety mechanism protects crusher and motor from damage.

- Efficient Design: Strong top crushing stroke reduces abrasion and gouging.

- Low Fines Production: Minimizes fine particle generation for efficient crushing.

- Minimal Foundation Requirements: Balanced moving parts reduce foundation costs.

- Wide Range of Applications: Suitable for tough materials like rock and ferroalloys.

- Strength and Durability: Superior compressive crushing action ensures durability.

- Primary Metal Industries: Accepted in primary metal industries for high-strength materials.

Industries

Cement Production • Chemical Processing • Manufactured Products Preparation

Mining Operations (Aggregate, Sand & Gravel, Potash, and Other Minerals)

Technical Details

- Jaw plates can be either smooth or corrugated

- 250 to 400 strokes per minute

- Fully 95% of the drive motor power is used for crushing

5% of the power is needed to move the jaw itself - Accept feed sizes up to 38″ (965 mm)

- Produce a nominal product size as small as 3/4″ (19 mm)