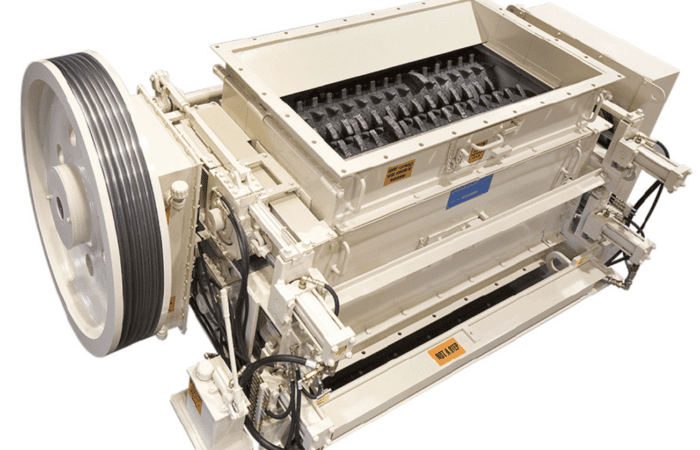

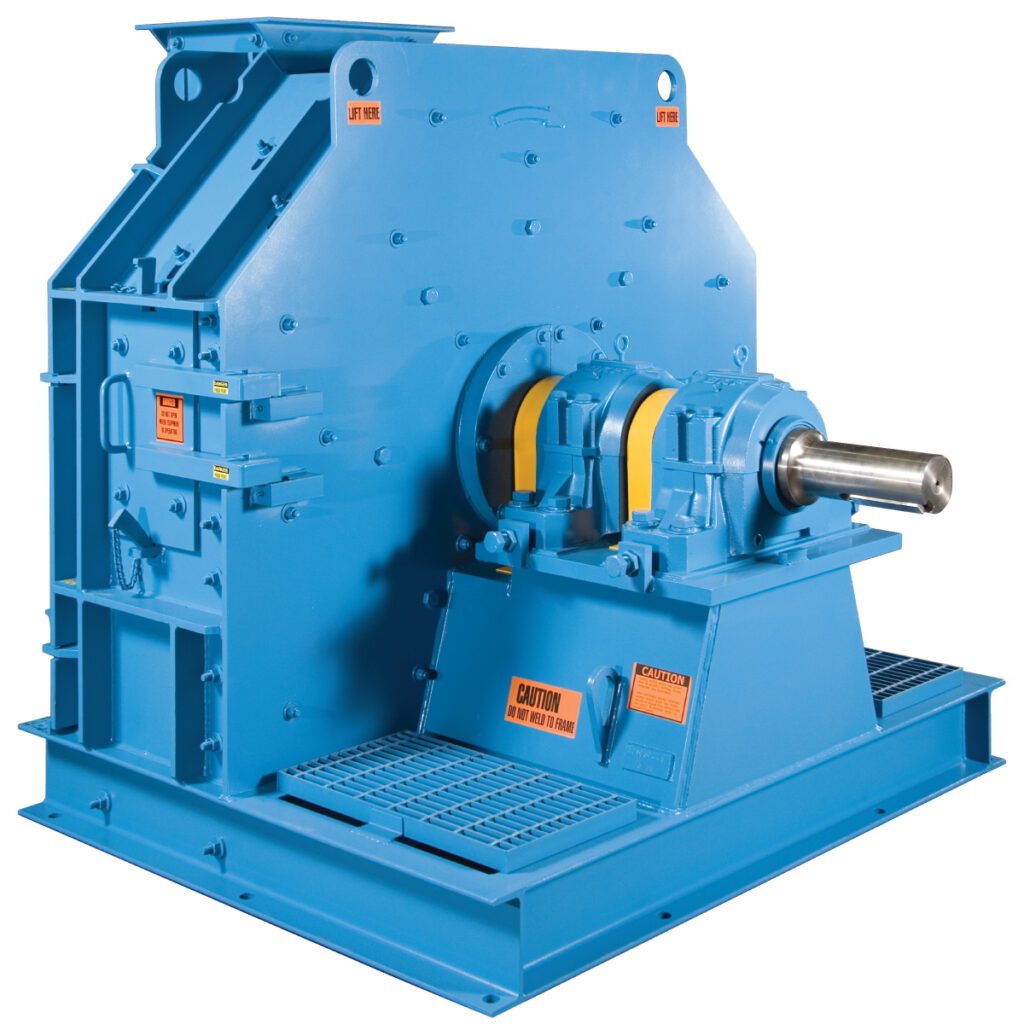

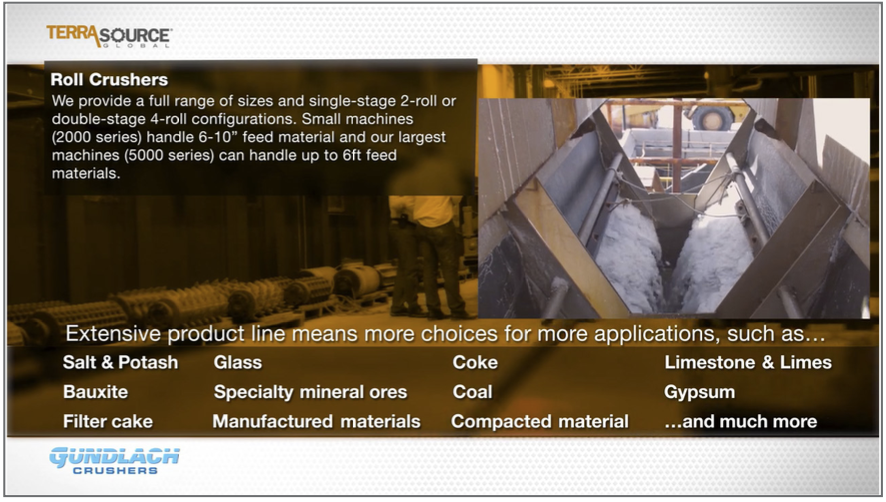

Why Slant-Flow® screen grates are the best choice for your business pact areas of the hammerto provide greater resiliency thanbrittle, bi-metal parts. These enhancements–designedexactly to customer specifications–make these parts the preferred solution for industrialoperations requiring the ultimate mix of superior impact-zone performance and up to 4x* longerwear than third-party products or chromoly alloy steel.Precision OEM Slant-Flow® Screen Grates—the TOP choice for productivity, durability, andvalue!Premium OEM Line of Jeffrey Rader Slant-Flow® Screen Grates with Advanced Wear-ResistantSteel Are Trusted Worldwide.Now, 4–8-week lead time on all replacement Slant-Flow® Screen Grates!PRECISION OEM SLANT-FLOW® SCREEN GRATESThe top choice for productivity, durability, and value.As you know, nothing beats TerraSource Global’s Jeffrey Rader brand of EZ-Access™Hogs forchip processing power, reliability,performance,and ease of maintenance. The precisionengineering of these machines, supported by our rugged and durable OEM parts, means you’regetting the most scalable, long-lasting, and cost-effective solutions for your specific chipprocessing applications.Using original OEM replacement parts such as hammers, liners and screen grates maximizesthe long-term value of your machine and ensures ongoing access to TerraSource Global’sextensive technical and application expertise that third-party vendors can’t match.Why Slant-Flow® Screen Grates are the best choice for your business.Not only does our improved 4–8-week lead time help keep your operation running with minimaldowntime, but you also get peace ofmind knowing that you’re using the most productive and

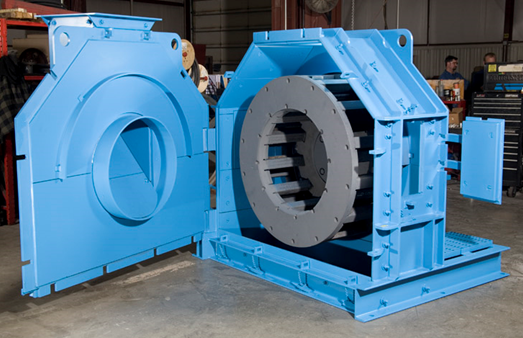

cost-effective screen grate on the market. TerraSource Global’s Slant-Flow® screen grates beatthird-party offerings by giving you…More shredding action: faster material evacuation–Our Slant-Flow®Screen Grates are angledinto the flow of material being shredded, meaning higher performance, less wear on the gratesand hammers and more uniform product size.Less clogging and diminished fines and pins–Third-party vendors cannot fully and consistentlymatch our unique slant flow screen design that is built specifically for the highest capacityprocessing.Minimized chances of operational failure–All our parts are built to original OEM specs, withverified highest quality materials, for better performance and less chance of failures that cancause widespread damage to other parts such as hammers, rotors, and so on.Warranty on workmanship–All of our parts are fabricated by AWS certified welders, which iswhy we are confident in offering warranties on workmanship. Most third-party vendors can’t offersuch assurances.INTRODUCING THE PREMIUM BRUTE ARMOR™ LINE OF JEFFREY RADER SLANT-FLOW® SCREEN GRATES WITH ADVANCE WEAR-RESISTANT STEEL.Customers worldwide trust our OEM Slant-Flow® Screen Grates toprovide the mostproductivity, durability, and value for their business. And for operations demanding minimummaintenance and maximum tramp-metal resistance, we’re proud to introduce Brute Armor™premium screen grate materials, the strongest and longest-wearing product on the market. Theone-two punch of Brute Armor’s chemistry and proprietary production processes means:• The highest level of durability, efficiency, and performance.• Maximum up-time for your operations. Cages are built to withstand the toughest conditions.How?• Tight chemistry controls assure that our premium alloys produce the most wear-resistant steel.• Enriched nickel content and our proprietary heat treatment process provide a level oftoughness and strength that optimizes resistance to deformation and gouging by tramp impacts.• Precisely controlled carbon and hydrogen levels ensure high-quality weld fusion.• Our unique heat-treatment process maximizes wear life by delivering optimal hardnessthroughout the entire plate thickness, unlike common AR plates.Precision OEM Slant-Flow® Screen Grates—the TOP choice for productivity, durability, andvalue!Original OEM replacement parts such as hammers, liners and screen grates maximize the long-term value of your machine and ensure ongoing access to TerraSource Global’s extensivetechnical and application expertise that third-party vendors can’t match.WhySlant-Flow® Screen Grates are the best choice for your business.More Shredding Action, Faster Material EvacuationOur Slant-Flow® Screen Grates are angled into the flow of material being shredded, meaninghigher performance, less wear on the grates andhammers and more uniform product size.