NFE Electromechanical Vibrating Feeders

Designed for user convenience, Jeffrey Rader feeders boast easy access to serviceable components, minimizing downtime. The latest innovation, the NFE Electromechanical Vibrating Feeder, offers enhanced efficiency and safety with its pure balanced linear motion and near-zero maintenance design. Featuring precision tuning and rugged construction, these feeders excel in handling various materials, from crushed stone to industrial substances, ensuring reduced energy consumption, simplified maintenance, and superior safety standards.

Suspended Applications

New Drive System

Supported Applications

Features and Benefits:

- Rugged Deck Design: Enhanced structure for handling large, lumpy materials reliably.

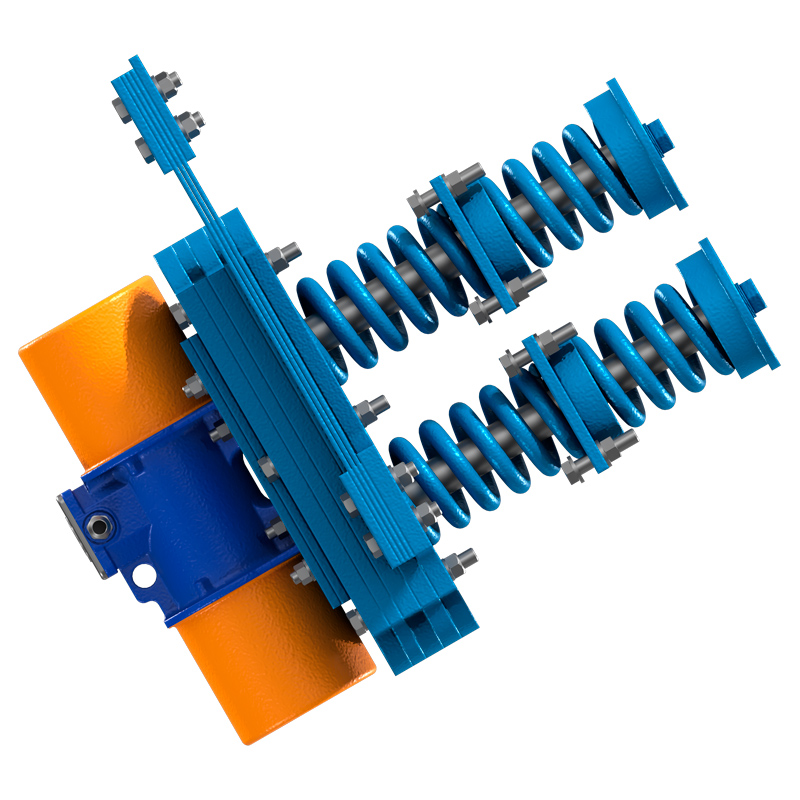

- Exciter Assembly: Transmits vibrating forces for material conveyance, with easily accessible external vibration motors.

- Vibration-Resistant Spring Retention: Steel springs with low damping coefficient for stability and reduced power consumption.

- Maintenance-Free Vibrating Motors: Reliable motors with sealed-for-life bearings.

- Frequency Controls: Remote or local controllers for automatic or manual operation, compatible with plant PLCs.

- Precision Sub-Resonant Tuning: Drives large masses with minimal horsepower for efficient operation.

- Minimum Stroke Variation: Stable performance under varying load conditions, with smooth capacity adjustments.

- Increased Capacities & Dimensions: Innovative design for higher capacities and efficient feeders, with options for optimized hopper design.

- Reduced Energy Costs: Efficient design minimizes power consumption.

- Easier Maintenance: Accessible components and low-maintenance motors.

- Better Safety: Enhanced design features for safer operation.

- Conformité Européenne (CE) Compliant: Meets European safety standards for equipment.

Features and Benefits:

- Rugged Deck Design: Enhanced structure for handling large, lumpy materials reliably.

- Exciter Assembly: Transmits vibrating forces for material conveyance, with easily accessible external vibration motors.

- Vibration-Resistant Spring Retention: Steel springs with low damping coefficient for stability and reduced power consumption.

- Maintenance-Free Vibrating Motors: Reliable motors with sealed-for-life bearings.

- Frequency Controls: Remote or local controllers for automatic or manual operation, compatible with plant PLCs.

- Precision Sub-Resonant Tuning: Drives large masses with minimal horsepower for efficient operation.

- Minimum Stroke Variation: Stable performance under varying load conditions, with smooth capacity adjustments.

- Increased Capacities & Dimensions: Innovative design for higher capacities and efficient feeders, with options for optimized hopper design.

- Reduced Energy Costs: Efficient design minimizes power consumption.

- Easier Maintenance: Accessible components and low-maintenance motors.

- Better Safety: Enhanced design features for safer operation.

- Conformité Européenne (CE) Compliant: Meets European safety standards for equipment.

Technical Details

- Sub-resonant tuning–less horsepower required (energy savings)

- “Near-Zero” maintenance

- Pure linear motion from the balanced two-motor drive system

- Suspended or supported mounting options

- 100% range of control

- Manual or auto operation (4-20 mA input signal)

- Control enclosure: NEMA 12 (standard), 4 or 4X (optional)

- Variable frequency controller includes dynamic braking resistor and AC input line reactor

- Steel pre-compressed coupling springs.

- Low damping coefficient that minimizes power consumption.

- Constant spring rate compared to rubber springs

- 100% maintenance-free vibration motors.

- Power supply 115 – 690V, 50 & 60 Hz.

- Horsepower sized per application

- Optional motor ATEX rating available

- Variety of deck sizes and configurations available

- High Burden-to-energy ratio

- Sub-resonant tuning–less horsepower required (energy savings)

- “Near-Zero” maintenance

- Pure linear motion from the balanced two-motor drive system

- Suspended or supported mounting options

- 100% range of control

- Manual or auto operation (4-20 mA input signal)

- Control enclosure: NEMA 12 (standard), 4 or 4X (optional)

- Variable frequency controller includes dynamic braking resistor and AC input line reactor

- Steel pre-compressed coupling springs.

- Low damping coefficient that minimizes power consumption.

- Constant spring rate compared to rubber springs

- 100% maintenance-free vibration motors.

- Power supply 115 – 690V, 50 & 60 Hz.

- Horsepower sized per application

- Optional motor ATEX rating available

- Variety of deck sizes and configurations available

- High Burden-to-energy ratio