Single Roll Crushers (SRC)

Discover the efficiency of Pennsylvania Crusher brand single roll crushers for precise size reduction of materials like coal, petroleum coke, and lignite. Employing three distinct methods—impact, shear, and compression—these compact crushers boast large mouths that effortlessly accept sizable slabs, ensuring thorough crushing. The Type K model, suitable for materials with a compressive strength of 8,000 p.s.i. or less, excels as a lump breaker for various substances. Featuring low profiles, superior roll assemblies, and minimal fines production, these crushers offer versatility and reliability. With multiple feeding options and adjustable output sizes, Pennsylvania Crusher single roll crushers are the solution for accurate size reduction in confined spaces and demanding applications.

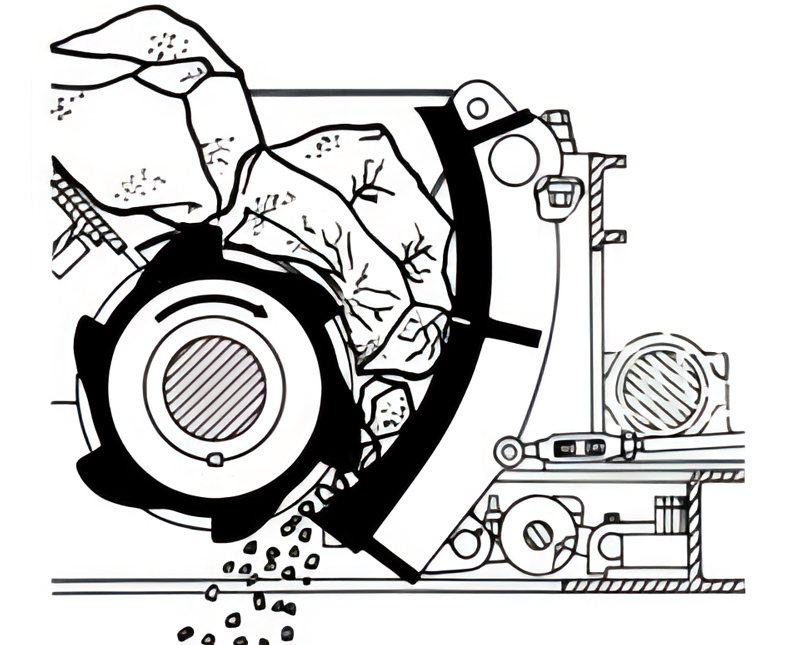

Operational Illustration

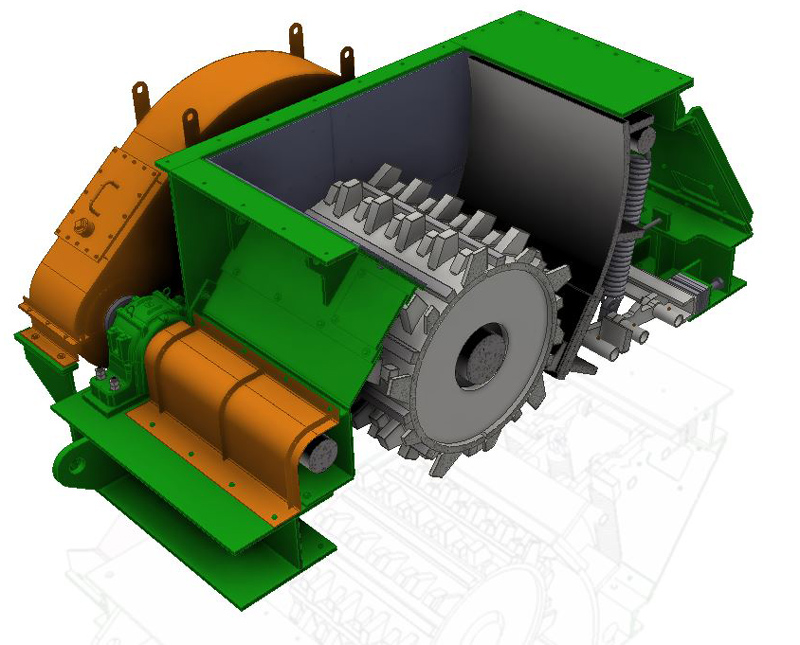

Ready for Shipment

Type-K ATEX Rated Sectional Drawing

Features and Benefits

- Three Methods of Reduction: Impact, shear, and compression methods for efficient material reduction.

- Compact Design: Large mouth for accepting large slabs in a compact structure.

- Curved Breaker Plates: Ensures proper crushing without allowing large slabs to pass through.

- Low Profile: Fits easily in limited spaces and under dump hoppers.

- Superior Roll Assembly: Teeth securely fixed, minimizing loosening.

- Minimal Fines Production: Fractures material along natural lines, reducing fines.

- No Screen Bars: Prevents re-crushing, further reducing fines.

- Low Power Requirement: Operates at low speeds, minimizing power demand.

- Multiple Models: Cater to varying material strengths and applications.

- Accurate Size Reduction: Effective for materials with moderate to high compression strength.

- Open Bottom Discharge: Allows sized material to fall through without re-crushing.

- Product Size Control: Gap adjustment for precise output size control.

- Easy Adjustment: Shim arrangement for quick output size adjustments.

- Flexible Feeding Options: Choke-fed or continuous from various equipment.

- Efficient Material Reduction: Impact, shear, and compression ensure effective reduction.

- Space-saving Design: Fits well in limited spaces.

- Reduced Fines Production: Minimizes fines for better material quality.

- Energy Efficiency: Low-speed operation leads to cost savings.

- Versatile Application: Suitable for a range of materials.

- Controlled Output Size: Easy adjustment for precise output control.

- No Material Recirculation: Maintains product integrity with open bottom discharge.

- Reliable Performance: Secure assembly for consistent operation.

- Ease of Maintenance: Simple adjustments and robust design for easy maintenance.

- Flexibility in Feeding: Integrates seamlessly with various feeding systems.

Features and Benefits

- Three Methods of Reduction: Impact, shear, and compression methods for efficient material reduction.

- Compact Design: Large mouth for accepting large slabs in a compact structure.

- Curved Breaker Plates: Ensures proper crushing without allowing large slabs to pass through.

- Low Profile: Fits easily in limited spaces and under dump hoppers.

- Superior Roll Assembly: Teeth securely fixed, minimizing loosening.

- Minimal Fines Production: Fractures material along natural lines, reducing fines.

- No Screen Bars: Prevents re-crushing, further reducing fines.

- Low Power Requirement: Operates at low speeds, minimizing power demand.

- Multiple Models: Cater to varying material strengths and applications.

- Accurate Size Reduction: Effective for materials with moderate to high compression strength.

- Open Bottom Discharge: Allows sized material to fall through without re-crushing.

- Product Size Control: Gap adjustment for precise output size control.

- Easy Adjustment: Shim arrangement for quick output size adjustments.

- Flexible Feeding Options: Choke-fed or continuous from various equipment.

- Efficient Material Reduction: Impact, shear, and compression ensure effective reduction.

- Space-saving Design: Fits well in limited spaces.

- Reduced Fines Production: Minimizes fines for better material quality.

- Energy Efficiency: Low-speed operation leads to cost savings.

- Versatile Application: Suitable for a range of materials.

- Controlled Output Size: Easy adjustment for precise output control.

- No Material Recirculation: Maintains product integrity with open bottom discharge.

- Reliable Performance: Secure assembly for consistent operation.

- Ease of Maintenance: Simple adjustments and robust design for easy maintenance.

- Flexibility in Feeding: Integrates seamlessly with various feeding systems.

Industries

Cement Production • Chemical Processing • Mining Operations (Aggregate, Sand & Gravel, Coal, Gypsum, and Other Minerals)

Petroleum Coke Processing • Power Generation • Steel Production

Technical Details

- Frame: ASTM A36 Fabricated Steel Plate

- Breaker Plates & Wear Plates: AISI 1040/1045 Hot rolled Carbon-Manganese Steel

- Breaker Plates Thickness: 1” (25 mm) thick front plate with 1” (25 mm) ribs. Screw adjustment with shims for breaker plate adjustment

- Roll Shell: AISI 1040/1045 Hot rolled Carbon-Manganese Steel – 1¼” thick (32 mm)

- Roll Shaft: Hot Rolled Steel AISI 1141

- Roll Shaft Bearings: Self-Aligning Spherical Roller

- Drive Shaft: Hot Rolled Steel AISI 1141

- Drive Shaft Bearings: Self Aligning Spherical Roller, Tapered Bore Bearings

Shaft Standard Lubrication is grease - Bearing Housings: Cast Iron, Split with Labyrinth Seals

- Gear Rim Material: AISI 1045 Hot rolled Carbon-Manganese Steel

- Gear Web & Hub Material: ASTM A36 Fabricated Steel

- Pinion Material: ASTM A668 Class E Forged Heat Treated Steel

- B10 Bearing Life: >100,000 hours

- Frame: ASTM A36 Fabricated Steel Plate

- Breaker Plates & Wear Plates: AISI 1040/1045 Hot rolled Carbon-Manganese Steel

- Breaker Plates Thickness: 1” (25 mm) thick front plate with 1” (25 mm) ribs. Screw adjustment with shims for breaker plate adjustment

- Roll Shell: AISI 1040/1045 Hot rolled Carbon-Manganese Steel – 1¼” thick (32 mm)

- Roll Shaft: Hot Rolled Steel AISI 1141

- Roll Shaft Bearings: Self-Aligning Spherical Roller

- Drive Shaft: Hot Rolled Steel AISI 1141

- Drive Shaft Bearings: Self Aligning Spherical Roller, Tapered Bore Bearings

Shaft Standard Lubrication is grease - Bearing Housings: Cast Iron, Split with Labyrinth Seals

- Gear Rim Material: AISI 1045 Hot rolled Carbon-Manganese Steel

- Gear Web & Hub Material: ASTM A36 Fabricated Steel

- Pinion Material: ASTM A668 Class E Forged Heat Treated Steel

- B10 Bearing Life: >100,000 hours