Systems - Biomass Material Handling

Image Title

Image Title

Image Title

Air Density Separator

Features/Advantages:

Features/Advantages

Another Quality Component from the Leader in Chip Processing Technology

Jeffrey Rader pioneered the use of vacuum air systems to remove chip contaminants such as rocks, knots and metal over 40 years ago. Our Air Density Separator’s uniquely-designed control system provides for optimal removal efficiency. The versatility of the ADS provides flexibility in locating chip conditioners and Chip-Sizer™ rechippers, saving costly space and reducing capital investment.

The ADS system’s unique design allows for a curtain of air to be pulled across an adjustable separation chamber. Rocks, knots and unwanted debris drop out of the flow of material at this controlled separation zone while accepts are conveyed to a cyclone.

Aside from protecting downstream equipment, the system’s ability to remove knots and compressed wood greatly improves the pulping process and helps eliminate pulping rejects.

Each ADS system is custom tailored to accommodate your specific process requirement resulting in the elimination of unnecessary energy consumption.

Applications

features and benefits of systems and equipment for biomass and alternative fuels:

Applications: Jeffrey Rader equipment supports various applications in biomass energy generation, including fluidized bed boilers, stoker boilers, cyclone and corner fired boilers, and more. Experience in handling a wide range of biomass and alternative fuels like wood chips, waste wood, sawdust, straw, pellets, coal, and others. Truck Dumpers & Receiving Bunkers: Manufactures truck dumpers, screw hoppers, and chain receiving bunkers for self-unloading trucks. Advanced engineering and heavy-duty construction ensure dependable operation, fast cycle times, improved productivity, and reliability. Fuel Preparation Size Reduction & Screening: Offers primary and secondary shredding & crushing systems, fine grinding for PC boilers, air density separation systems, and disc screens. Gyratory screens and flexible deck screens for efficient removal of oversized materials. Conveying & Material Handling: Complete material handling systems with pneumatic and mechanical conveying systems. Ruggedly built rotary valves, cyclones, ducting, and blowers designed for tough, high-pressure applications. Mechanical conveying systems include chain conveyors, screw conveyors, and bucket elevators. Storage & Reclaim: Equipment and systems for stacking, storing, and reclaiming wood chips, biomass, and RDF products. Storage solutions include open pile, metering bins, and circular silos. Reclaim systems with traveling linear screws, cone bottom screw reclaimers, and top-pile stacker/reclaimers ensure a constant flow of materials. Boiler Fuel Feed Systems: Mechanical and pneumatic feed systems tailored to meet storage, metering, and feed rate requirements of boilers. Equipment includes day bins, silos, conveyors, rotary airlock feeders, and fine grinding systems. Capable of handling fuel feed rates from 3 to over 200 tons per hour. The benefits include optimized boiler operations, improved productivity, reliable performance under challenging conditions, and customized solutions for specific fuel handling needs.

Technical Details

- Technical data available upon request.

Fill out our contact us form or email info@terrasource.com.

Resources

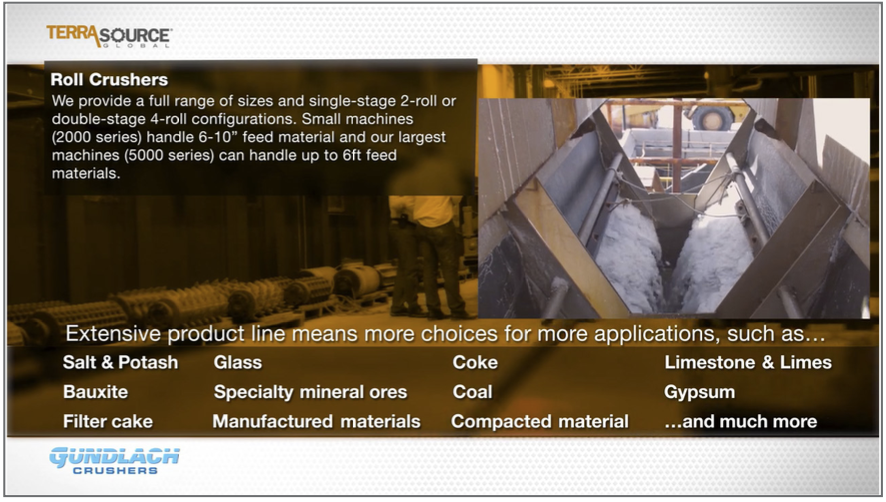

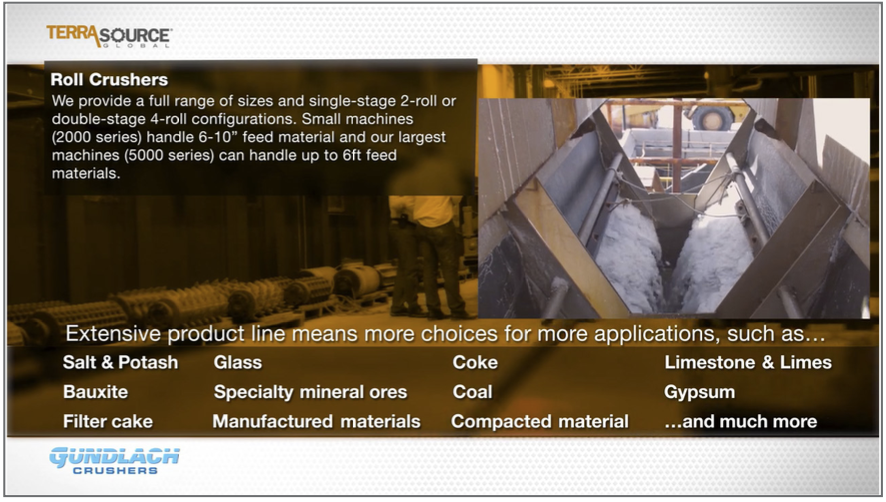

Gundlach Crushers Product Line Video

Roll Crushers Application Webinar Video

Potash 101 Webinar Video

Product Brochure