TubeFeeder®

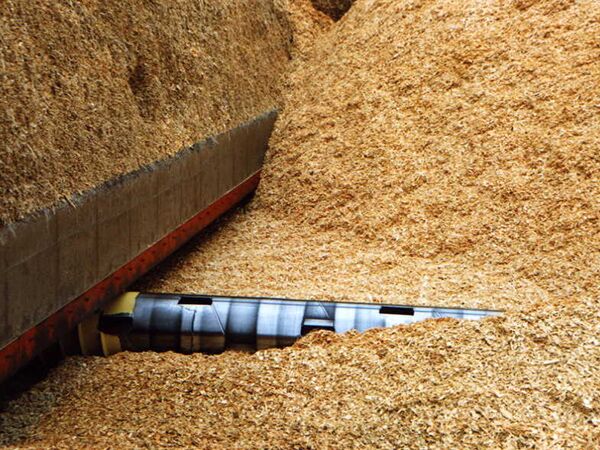

The TubeFeeder® by Jeffrey Rader brand revolutionizes material reclaiming with its innovative design. It is available in two different configurations: the Traditional System and the Rotating System. Both versions deliver superior efficiency and performance compared to conventional reclaimers, with patented technology that supports continuous 24/7 operation, minimal downtime, and energy consumption reduced by over 70%. Its unique under-pile configuration minimizes shear forces, extending component wear-life and maintaining product quality. Whether utilizing the Traditional System or the Rotating System, the TubeFeeder® ensures uniform reclaiming in any travel direction, precise homogenization, and the flexibility to handle a wide range of materials. the TubeFeeder® stands as the optimal solution for biomass energy plants, pulp and paper industries, and beyond—boosting productivity while reducing operational costs and environmental impact.

Activators Break Frozen Chip Clumps

Optimized Homogenization

Uniform Draw Down

Features/Benefits:

Energy Efficiency: Reduced power consumption compared to screw reclaimers. Lowers operational costs and supports sustainability efforts.

Protection from Head Load: Closed force system eliminates thrust loads into building structure. Reduces equipment wear, minimizing maintenance costs.

Shear Force Reduction: Minimizes shear forces transmitted into materials. Extends screw wear-life, reducing downtime and replacements.

Minimized Product Degradation: Prevents product degradation into fines during operation. Maintains product quality, reducing waste.

Consistent Reclaim Conditions: Ensures consistent operation independently of direction and height. Provides reliable and uniform reclaiming, optimizing efficiency.

Precise Reclaim Rate: High accuracy on low out-feed rates and adjustable reclaim rate. Enables precise material flow control, enhancing process quality.

First-in, First-out Reclaim: Utilizes true first-in, first-out and mass flow conditions. Maintains material rotation, ensuring quality and consistency.

Homogenization of Material: Precise blending and homogenization of reclaimed product. Improves fuel consistency and combustion efficiency.

Versatility and Adaptability: Reclaims various materials including wood chips and biomass. Widens applicability, ensuring versatility in material handling.

Reduced Footprint and Structural Costs: Minimized infrastructure requirements. Lowers investment and simplifies civil works, saving costs.

Extended Wear Life: 3-5 times longer wear life than traditional reclaimers. Enhances equipment durability, reducing downtime.

Cold Weather Performance: Handles frozen lumps and oversized bodies. Maintains consistent operation in adverse conditions.

Control and Process Optimization: Allows precise process parameter control. Optimizes efficiency and overall performance.

Sustainable Solution: Contributes to energy efficiency and carbon reduction. Aligns with sustainability goals, saving energy.

Reliable Performance: Designed for continuous 24/7 operation. Provides consistent performance and uptime.

Energy Efficiency: Reduced power consumption compared to screw reclaimers. Lowers operational costs and supports sustainability efforts.

Protection from Head Load: Closed force system eliminates thrust loads into building structure. Reduces equipment wear, minimizing maintenance costs.

Shear Force Reduction: Minimizes shear forces transmitted into materials. Extends screw wear-life, reducing downtime and replacements.

Minimized Product Degradation: Prevents product degradation into fines during operation. Maintains product quality, reducing waste.

Consistent Reclaim Conditions: Ensures consistent operation independently of direction and height. Provides reliable and uniform reclaiming, optimizing efficiency.

Precise Reclaim Rate: High accuracy on low out-feed rates and adjustable reclaim rate. Enables precise material flow control, enhancing process quality.

First-in, First-out Reclaim: Utilizes true first-in, first-out and mass flow conditions. Maintains material rotation, ensuring quality and consistency.

Homogenization of Material: Precise blending and homogenization of reclaimed product. Improves fuel consistency and combustion efficiency.

Versatility and Adaptability: Reclaims various materials including wood chips and biomass. Widens applicability, ensuring versatility in material handling.

Reduced Footprint and Structural Costs: Minimized infrastructure requirements. Lowers investment and simplifies civil works, saving costs.

Extended Wear Life: 3-5 times longer wear life than traditional reclaimers. Enhances equipment durability, reducing downtime.

Cold Weather Performance: Handles frozen lumps and oversized bodies. Maintains consistent operation in adverse conditions.

Control and Process Optimization: Allows precise process parameter control. Optimizes efficiency and overall performance.

Sustainable Solution: Contributes to energy efficiency and carbon reduction. Aligns with sustainability goals, saving energy.

Reliable Performance: Designed for continuous 24/7 operation. Provides consistent performance and uptime.

Industries

Agricultural/Food Processing • Biofuels & Pellets Production • Biomass Energy Processing • Power Generation

Pulp & Paper Manufacturing • Renewable Power Production • Sawmill Operations • Wood Products / Furniture Manufacturing

Technical Details

- Storage capacities can range from 100 m3 to over 1,000,000 m3 with reclaim rates ranging from 10 to 1000 m3/hr

- Variable speed drive controls the tube rotation speed and the discharge rate

- Outside tube rotates at 1-10 rpm

- Screw conveyor operates inside the tube at a fixed rpm, typically 40 rpm