Clinker Crusher

Introducing the Clinker Crusher by Pennsylvania Crusher Brand, a revolutionary solution for reducing bottom ash or clinker produced in utility and industrial power plants. With its unique design and advanced technology, this crusher offers unparalleled advantages over traditional clinker grinders. Featuring a special tooth pattern for enhanced crushing action and a patented seal to prevent leaks, it saves energy, reduces wear, and ensures shorter downtime. Direct replacements for existing equipment, these crushers boast stronger shaft designs and easier access for servicing. Available in various sizes and constructions, they deliver powerful crushing action and reliability, making them the preferred choice worldwide.

Features and Benefits:

- Direct Replacement Capability: Fits nearly every crusher make and model, interchangeable without fit-up problems.

- Energy Efficiency: Crushes without grinding, saving energy and reducing wear.

- Enhanced Reliability: Much greater reliability with a stronger shaft design.

- Leak Prevention: Patented sealing method prevents leakage, ensuring operational efficiency.

- Easy Servicing and Maintenance: Faster access for servicing, reduces downtime.

- More Powerful Crushing Action: Special tooth pattern for greater crushing force, ideal for hard clinker.

- Global Success: Proven track record worldwide, preferred choice for performance and reliability.

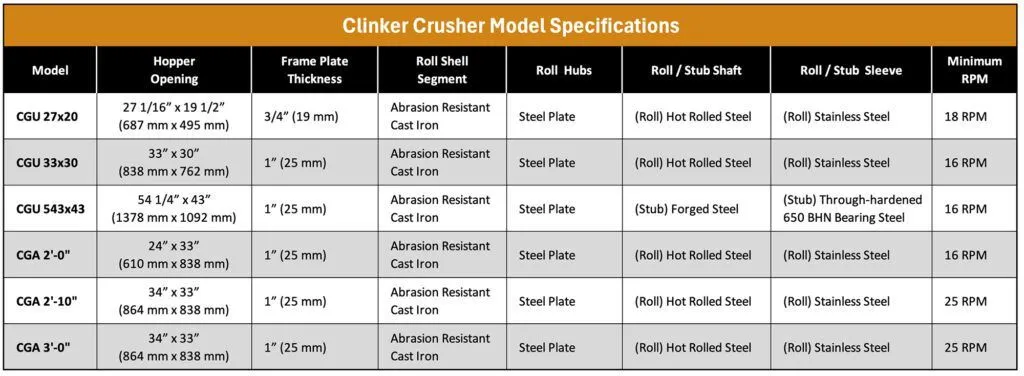

- Construction Features: Available in various sizes, options for carbon steel or stainless-steel construction.

- Roll Shaft Design: Square cross-section distributes torque better, resistant to deflection.

- Protected Bearings: Shielded from water seepage, minimizes shaft deflection.

- Roll Shell and Segments: Composed of six radial segments, high-chrome, white iron for durability.

- Frame-Wear Protection: Equipped with hard alloy liners, bolted side liners for easy replacement.

- Hinged Door Design: Facilitates easier servicing and jam clearing.

- Patented Seal: Innovative sealing method reduces environmental risk.

- Shorter Downtime: Maintenance tasks can be done without unit removal, reduces manpower and time.

- Direct Replacement Capability: Fits nearly every crusher make and model, interchangeable without fit-up problems.

- Energy Efficiency: Crushes without grinding, saving energy and reducing wear.

- Enhanced Reliability: Much greater reliability with a stronger shaft design.

- Leak Prevention: Patented sealing method prevents leakage, ensuring operational efficiency.

- Easy Servicing and Maintenance: Faster access for servicing, reduces downtime.

- More Powerful Crushing Action: Special tooth pattern for greater crushing force, ideal for hard clinker.

- Global Success: Proven track record worldwide, preferred choice for performance and reliability.

- Construction Features: Available in various sizes, options for carbon steel or stainless-steel construction.

- Roll Shaft Design: Square cross-section distributes torque better, resistant to deflection.

- Protected Bearings: Shielded from water seepage, minimizes shaft deflection.

- Roll Shell and Segments: Composed of six radial segments, high-chrome, white iron for durability.

- Frame-Wear Protection: Equipped with hard alloy liners, bolted side liners for easy replacement.

- Hinged Door Design: Facilitates easier servicing and jam clearing.

- Patented Seal: Innovative sealing method reduces environmental risk.

- Shorter Downtime: Maintenance tasks can be done without unit removal, reduces manpower and time.

Industries

Cement Production • Chemical Processing • Limestone & Lime Processing • Mining (Coal, Gypsum & Other Minerals)

Petroleum Coke Processing • Power Generation • Steel Production