CC4000 Chip Classifier

The Jeffrey Rader CC4000 Chip Classifier is the top choice for paper mills seeking precise chip thickness classification for quality control. This fully automated system, controlled by a computer with Microsoft Windows software, allows operators to define and measure chip thickness, a critical factor in chip cooking quality. With the ability to classify chips from 2mm to 23mm and provide instantaneous data with documentation, it offers significant advantages like superior sample repeatability, larger sample sizes, and customizable output formats. Plus, it’s low maintenance and easily integrates into existing systems. Join leading pulp and paper companies in relying on the CC4000 for efficient chip quality control and cost reduction.

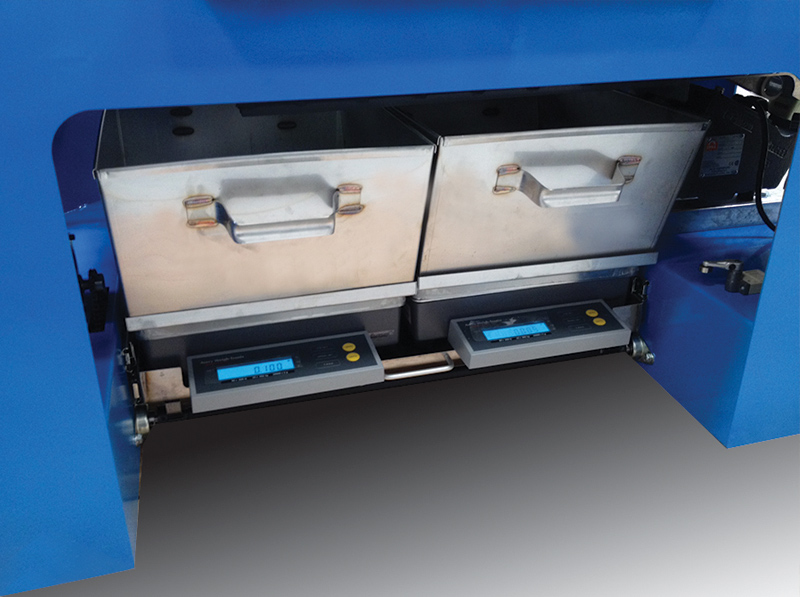

Automatic scale weigh bins ensure easy access to samples

Efficient classification and evaluation of chip quality

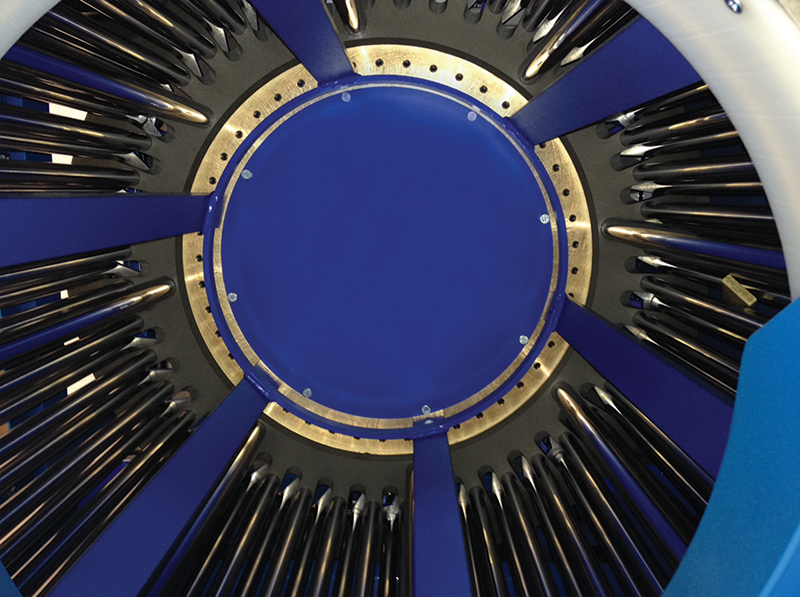

Patented bar configuration measures thickness of each chip

Features:

- Chip thickness classification from 2mm to 23mm that the operator can choose.

- Superior sample repeatability and accurate chip fraction separation (± 0.25mm).

- Can sample up to 4 times larger samples compared to other classifiers.

- Fully automated chip classification system.

- Real-time monitoring and control of all functions via computer with Microsoft Windows software.

- Customizable thickness settings for each batch of chips.

- Patented bar configuration for precise chip thickness measurement.

- Automatic scale weigh bins for easy sample access.

- Low maintenance design with enhanced access to parts.

- Modification of classification settings through PC application.

- Easy replacement of electrical components.

Technical Details

Weight –2,200 lbs.

Height –66.5 inches

Width –53 inches

Depth –31 inches

Electrical requirements –120 volts/ 60 Hz/ 20 amps

Drum dimensions –24” x 24”

Benefits:

- Approximates the individual micrometer measurement of each chip, ensuring high accuracy.

- Efficient classification and evaluation of chip quality with programmable thickness size selection.

- Provides instantaneous data with documentation for each classification.

- Easily save and retrieve sample test results for chip quality comparison.

- Reduces labor-intensive tasks associated with chip classification.

- Enhances access to parts for maintenance, reducing downtime.

- Enables total variability of chip thickness size selection, enhancing control over chip quality and production.

- Easy integration of data into larger enterprise systems for comprehensive analysis.

- Reliable monitoring and tracking of processing equipment and chip quality over time.

- Allows mill operators to define and measure chip thickness, reducing costs and ensuring high-value outputs.

- Preferred choice of leading companies in the pulp and paper industry for accurate wood chip classification.

- Seamless integration with other systems, making it an industry standard tool for quality control.

- Offers time savings, labor savings, and cost savings to pulp and paper mills.

- Customizable format of data output to meet specific requirements.

- Automatic scale weigh bins make sample handling convenient.

- Easy replacement of electrical components ensures minimal downtime.