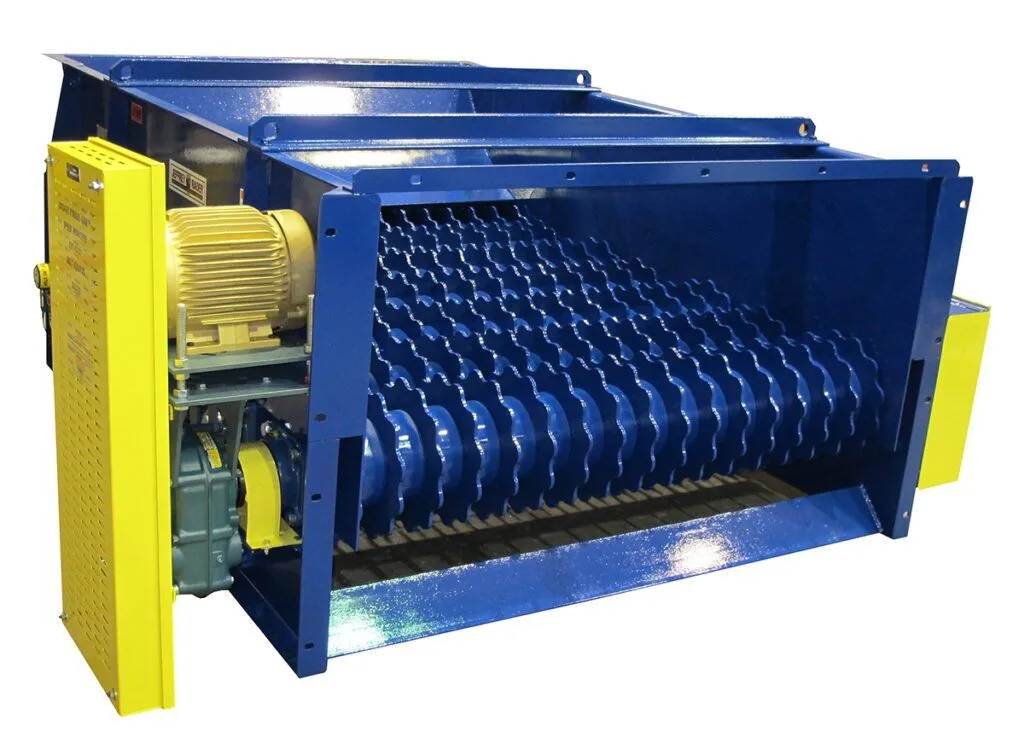

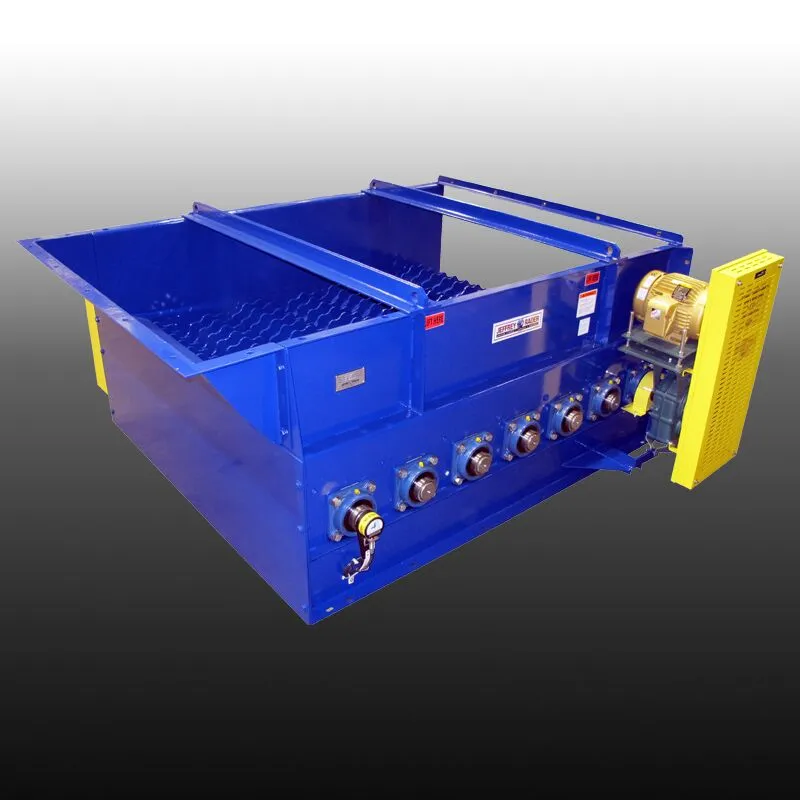

Jeffrey Rader Disc Screen (RDS)

The Jeffrey Rader Disc Screen (RDS) is the industry’s top choice for efficiently removing oversized rejects from unscreened wood chips, hog fuel, or bark. Engineered to your specific requirements, this heavy-duty scalping screen features a modular design for easy field configuration and offers exceptional advantages such as continuous material movement, self-cleaning for minimal downtime, and variable openings to screen out various materials. With a track record of unparalleled performance, Jeffrey Rader’s Disc Screen is the go-to solution for optimizing your wood chip processing operations.

Features:

- Versatile Wood Chip Screening: Designed for removing oversized rejects from unscreened wood chips, hog fuel, or bark.

- Continuous Material Movement: Utilizes rotating multi-toothed discs to continuously move material, shaking loose small particles while larger material is carried forward.

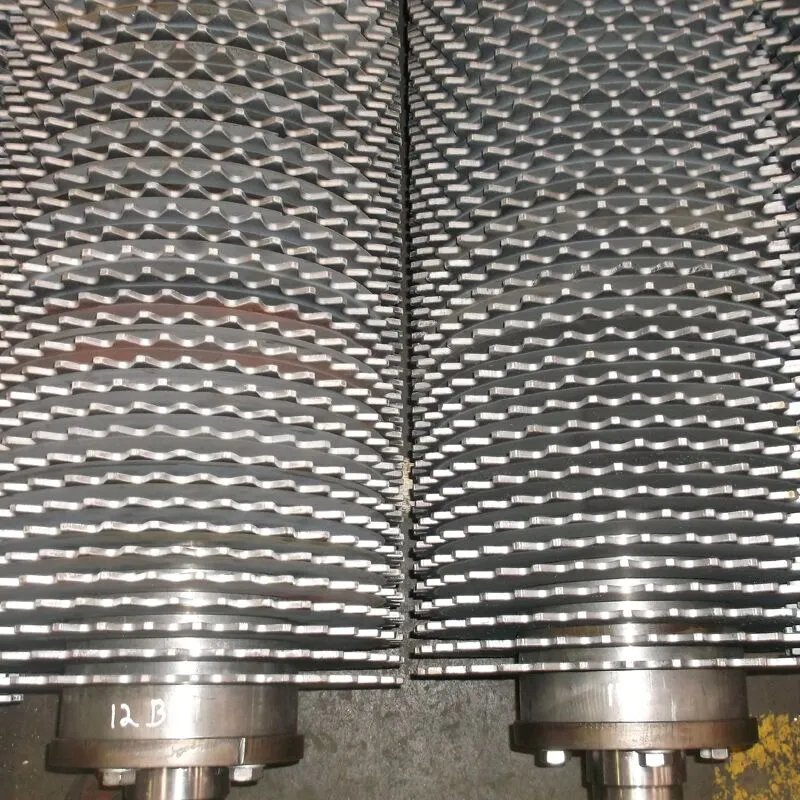

- Customizable Disc Profile: Engineers select the ideal disc profile, interface openings, and screen size for maximum screening efficiency based on the individual application.

- Removable Discs and Spacers: Discs and spacers can be easily removed and changed in the field for flexibility in screening requirements.

- Energy-Efficient Design: Compact design minimizes space requirements and ensures energy-efficient operation.

- Self-Cleaning: Designed for minimal downtime and higher volume production as rotating discs continually clear oversize material and interface openings remain clear.

- Discrete Separation: Allows for variable openings between discs to screen out specific materials like glass, grit, ceramic, aluminum, and large fibrous matter.

- Modifiable On-Site: Can be modified on-site by installing different length spacers to adapt to changing material characteristics.

- Engineered for Long Service Life: Built for rugged, nonstop service with routine maintenance, and easily accessible service points and components

Benefits:

- High Screening Efficiency: Maximizes the separation of desirable materials from incoming material.

- Continuous Operation: Suitable for 24-hour-a-day processing operations.

- Resource Recovery: Ideal for recovering valuable materials efficiently.

- Complete Material Examination: Ensures a high percentage of desired or undesired fractions are removed.

- Accurate Separation: Self-cleaning design maintains constant interface openings for precise material separation.

- High Throughput: Offers higher throughput compared to other screen systems due to conveying and bounding large fractions.

- Flexible Material Separation: Easily configurable to separate different materials by selecting the proper disc profile and interface spacing.

- Field Configurable: Modular design allows for easy field modifications, offering advantages over welded shaft designs.

Features:

- Versatile Wood Chip Screening: Designed for removing oversized rejects from unscreened wood chips, hog fuel, or bark.

- Continuous Material Movement: Utilizes rotating multi-toothed discs to continuously move material, shaking loose small particles while larger material is carried forward.

- Customizable Disc Profile: Engineers select the ideal disc profile, interface openings, and screen size for maximum screening efficiency based on the individual application.

- Removable Discs and Spacers: Discs and spacers can be easily removed and changed in the field for flexibility in screening requirements.

- Energy-Efficient Design: Compact design minimizes space requirements and ensures energy-efficient operation.

- Self-Cleaning: Designed for minimal downtime and higher volume production as rotating discs continually clear oversize material and interface openings remain clear.

- Discrete Separation: Allows for variable openings between discs to screen out specific materials like glass, grit, ceramic, aluminum, and large fibrous matter.

- Modifiable On-Site: Can be modified on-site by installing different length spacers to adapt to changing material characteristics.

- Engineered for Long Service Life: Built for rugged, nonstop service with routine maintenance, and easily accessible service points and components

Benefits:

- High Screening Efficiency: Maximizes the separation of desirable materials from incoming material.

- Continuous Operation: Suitable for 24-hour-a-day processing operations.

- Resource Recovery: Ideal for recovering valuable materials efficiently.

- Complete Material Examination: Ensures a high percentage of desired or undesired fractions are removed.

- Accurate Separation: Self-cleaning design maintains constant interface openings for precise material separation.

- High Throughput: Offers higher throughput compared to other screen systems due to conveying and bounding large fractions.

- Flexible Material Separation: Easily configurable to separate different materials by selecting the proper disc profile and interface spacing.

- Field Configurable: Modular design allows for easy field modifications, offering advantages over welded shaft designs.

Industries

Agricultural/Food Processing • Biofuels & Pellets Production • Biomass Energy Processing • Pulp & Paper Manufacturing • Recycling Operations • Renewable Power Production • Sawmill Operations • Waste Management • Wood Products / Furniture Manufacturing