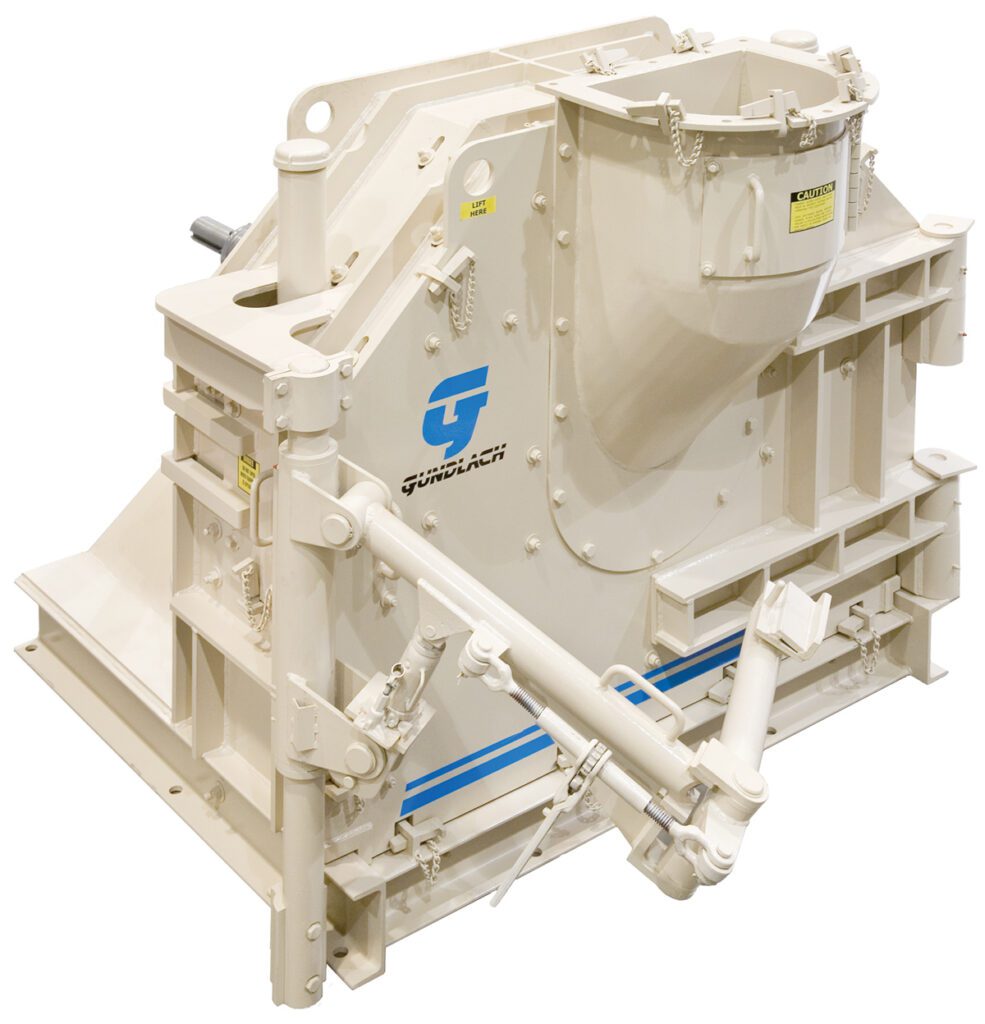

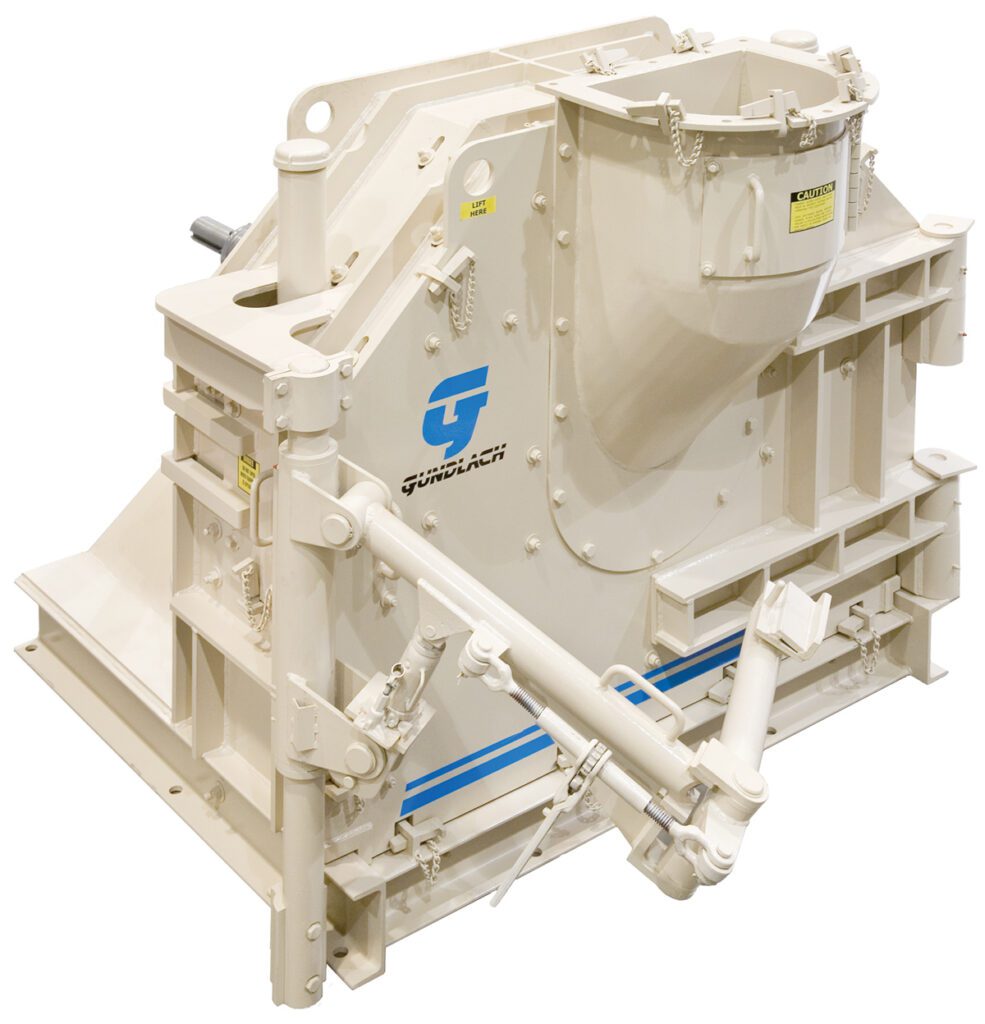

The Cage-Paktor® is a versatile crushing solution that excels in handling challenging materials, from wet and sticky substances to friable materials like coal and fertilizers. With the ability to crush from 100mm feeds to 2mm products, it offers economical impactor design, reducing power consumption and operating costs.

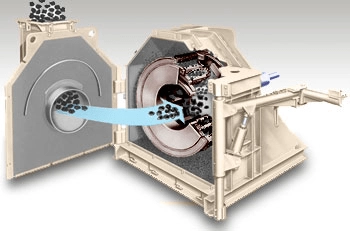

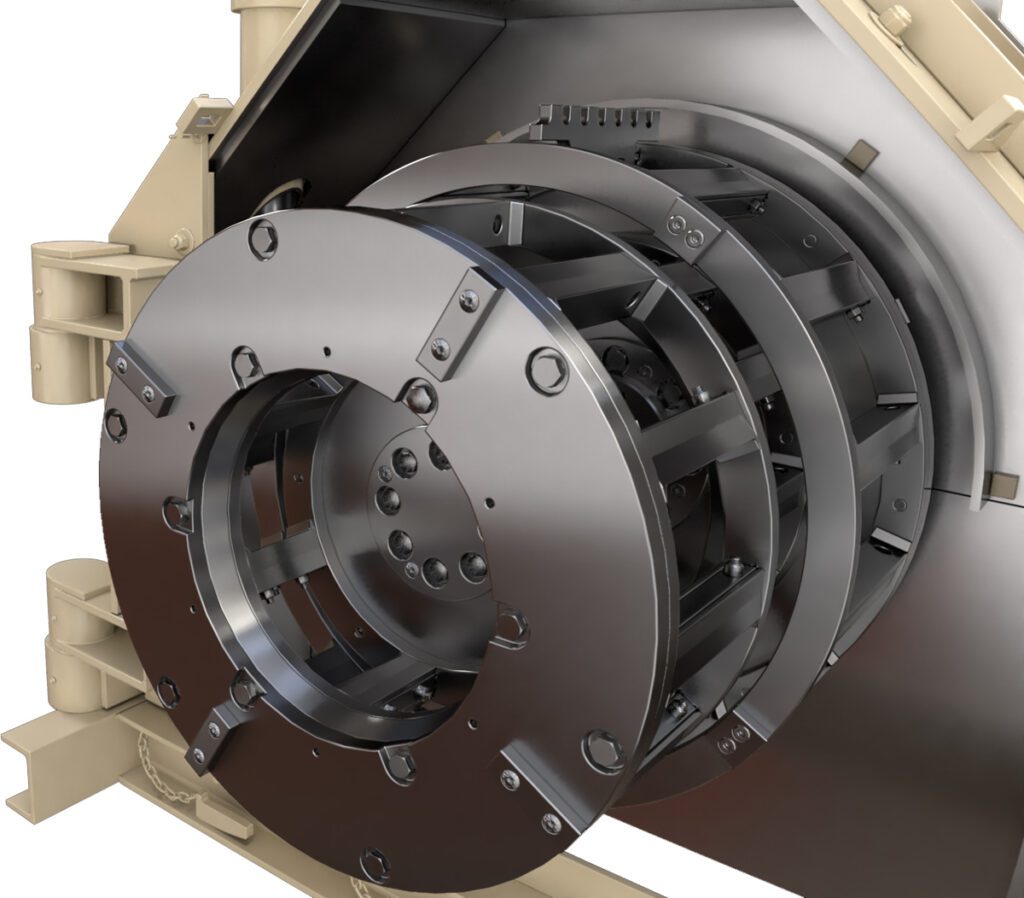

Its compact design saves floor space, and the exclusive air-cannon system prevents material buildup. Featuring a unique cage mill design, it simplifies maintenance with an optional cage jack and offers striking plate options for various material types. The Swing-away door on the Model 50 enhances maintenance convenience, making it a powerful, cost-effective choice for selective and uniform impact crushing needs.

The Cage-Paktor® is a versatile crushing solution that excels in handling challenging materials, from wet and sticky substances to friable materials like coal and fertilizers. With the ability to crush from 100mm feeds to 2mm products, it offers economical impactor design, reducing power consumption and operating costs. Its compact design saves floor space, and the exclusive air-cannon system prevents material buildup. Featuring a unique cage mill design, it simplifies maintenance with an optional cage jack and offers striking plate options for various material types. The Swing-away door on the Model 50 enhances maintenance convenience, making it a powerful, cost-effective choice for selective and uniform impact crushing needs.

Features and Benefits

When you’re dealing with wet, sticky or difficult-to-crush materials, the CAGE-PAKTOR® 1C3R delivers more features, more value and more crushing power for the dollar. Plus, it helps maximize your return on investment by maximizing your product yield from friable materials. Designed for efficient crushing from 100 mm feeds to 2 mm product, the CAGE-PAKTOR is ideal for a variety of materials such as coal, salts and metallurgical coal for making coke, as well as fertilizers such as potash, nitrogen and phosphate.

2C4R Model Features and Benefits

Cement Production • Chemical Processing

Limestone & Lime Processing • Mining Operations (Coal, Potash, and Other Minerals)

Petroleum Coke Processing • Power Generation

Steel Production

Cement Production • Chemical Processing • Limestone & Lime Processing • Mining Operations (Coal, Potash, and Other Minerals)

Petroleum Coke Processing • Power Generation • Steel Production

1C3R Cage Paktors (3 Rows of Striking Surfaces)

2C4R Cage Paktors (4 Rows of Striking Surfaces)

We use cookies to offer you a better experience, analyze site traffic, and serve targeted advertisements. By continuing to use this website, you consent to the use of cookies according to our cookie policy.

Manage your cookie preferences below:

Essential cookies enable basic functions and are necessary for the proper function of the website.

These cookies are needed for adding comments on this website.

Google Tag Manager simplifies the management of marketing tags on your website without code changes.

Statistics cookies collect information anonymously. This information helps us understand how visitors use our website.

You can find more information on our policy page - https://terrasource.com/cookie-policy/

Adding {{itemName}} to cart

Added {{itemName}} to cart