TKK Granulator

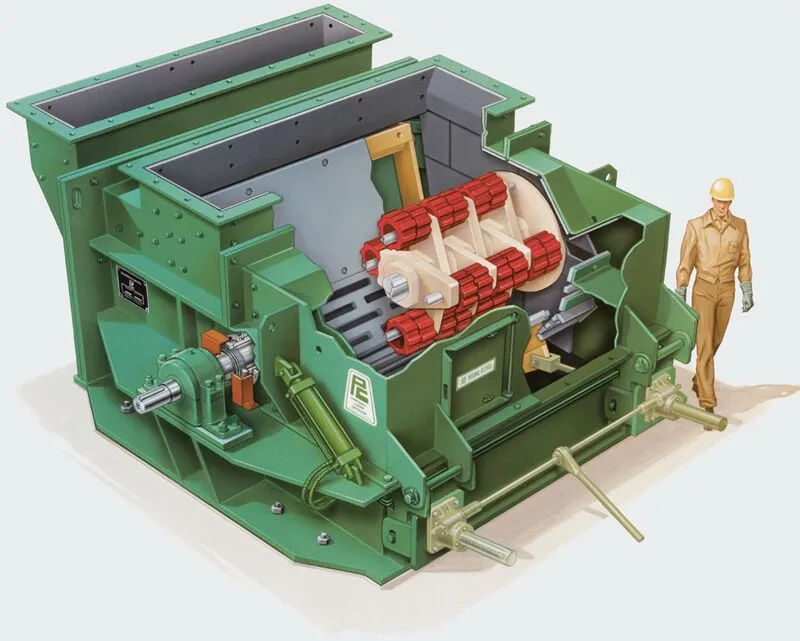

Pennsylvania Crusher’s GRANULATORS, featuring the renowned TKK Koal-King® model, excel in crushing a wide range of materials such as coal, limestone, and gypsum. Widely used in power plants, mines, cement plants, and more, the TKK Granulator stands out with its unmatched reduction capability and superior performance. Its innovative design includes features like interchangeable screen plates, slotted openings for increased capacity, and toothed ring forged steel hammers that minimize vibration. This crusher’s advantages extend to ease of maintenance, with bolted frame liners, hinged rear quadrants for full access, and clean-out doors. It even offers optional hydraulic cage door openers for added convenience. The TKK Granulator is the top choice for efficient, low-capacity crushing needs.

Granulator Rotor

Sugar Industry In Field Use

Section or Cutaway View

Features and Benefits of Pennsylvania Crusher Brand TKK Koal-King® Granulators:

- Versatility: Capable of processing wet, frozen, fine, and contaminated coals, adaptable to diverse materials and operating conditions.

- Widely Used: The globally preferred granulator with a track record of proven reliability across industries.

- Material Handling: Handles limestone, coal, gypsum, and friable materials and is suitable for power plants, mines, and cement plants.

- Reduction Capability: Capable of processing limestone, coal, gypsum, and other friable materials, making it ideal for use in power plants, mines, and cement plants.

- Minimizes Fines: Maximizes fines reduction and effectively handles wet, fine, and contaminated materials, enhancing overall material handling efficiency.

- Improved Crushing Efficiency: Toothed ring, forged steel hammers ensure efficient crushing with minimal vibration.

- Uniform Crushing: Optimized hammer placement ensures full cage coverage, resulting in consistently uniform crushing.

- Ease of Maintenance: Bolted frame liners, hinged rear quadrants, and clean-out doors for convenient maintenance and cleaning access, minimizing downtime and maintenance expenses.

- Bearing Housing Design: Split bearing housing design simplifies bearing maintenance and lubrication, eliminating the need for bearing removal.

- Optional Bypass Chutes: Extends equipment lifespan for pre-sized feed material.

- Enhanced Wear Materials: Durable wear materials and liners, customizable to enhance wear resistance.

- Hydraulic Cage Door Openers: Optional feature for simplified maintenance and adjustments, enhancing operational efficiency.

- Superior Technology: Enhanced access configuration and screen cage design featuring Duralife Hammers for prolonged durability.

- Crusher Protection: Channels non-crushable debris towards a tramp iron trap, safeguarding the crusher and minimizing the potential damage caused by foreign objects.

- No Flywheel: Eliminates the need for an external flywheel, simplifying maintenance and reducing hazards.

- Versatility: Capable of processing wet, frozen, fine, and contaminated coals, adaptable to diverse materials and operating conditions.

- Widely Used: The globally preferred granulator with a track record of proven reliability across industries.

- Material Handling: Handles limestone, coal, gypsum, and friable materials and is suitable for power plants, mines, and cement plants.

- Reduction Capability: Capable of processing limestone, coal, gypsum, and other friable materials, making it ideal for use in power plants, mines, and cement plants.

- Minimizes Fines: Maximizes fines reduction and effectively handles wet, fine, and contaminated materials, enhancing overall material handling efficiency.

- Improved Crushing Efficiency: Toothed ring, forged steel hammers ensure efficient crushing with minimal vibration.

- Uniform Crushing: Optimized hammer placement ensures full cage coverage, resulting in consistently uniform crushing.

- Ease of Maintenance: Bolted frame liners, hinged rear quadrants, and clean-out doors for convenient maintenance and cleaning access, minimizing downtime and maintenance expenses.

- Bearing Housing Design: Split bearing housing design simplifies bearing maintenance and lubrication, eliminating the need for bearing removal.

- Optional Bypass Chutes: Extends equipment lifespan for pre-sized feed material.

- Enhanced Wear Materials: Durable wear materials and liners, customizable to enhance wear resistance.

- Hydraulic Cage Door Openers: Optional feature for simplified maintenance and adjustments, enhancing operational efficiency.

- Superior Technology: Enhanced access configuration and screen cage design featuring Duralife Hammers for prolonged durability.

- Crusher Protection: Channels non-crushable debris towards a tramp iron trap, safeguarding the crusher and minimizing the potential damage caused by foreign objects.

- No Flywheel: Eliminates the need for an external flywheel, simplifying maintenance and reducing hazards.

Industries

Cement Production • Chemical Processing

Limestone & Lime Processing

Mining Operations (Coal, Gypsum, and Other Minerals) • Petroleum Coke Processing

Power Generation • Steel Production

Cement Production • Chemical Processing • Limestone & Lime Processing

Mining Operations (Coal, Gypsum, and Other Minerals) • Petroleum Coke Processing • Power Generation • Steel Production

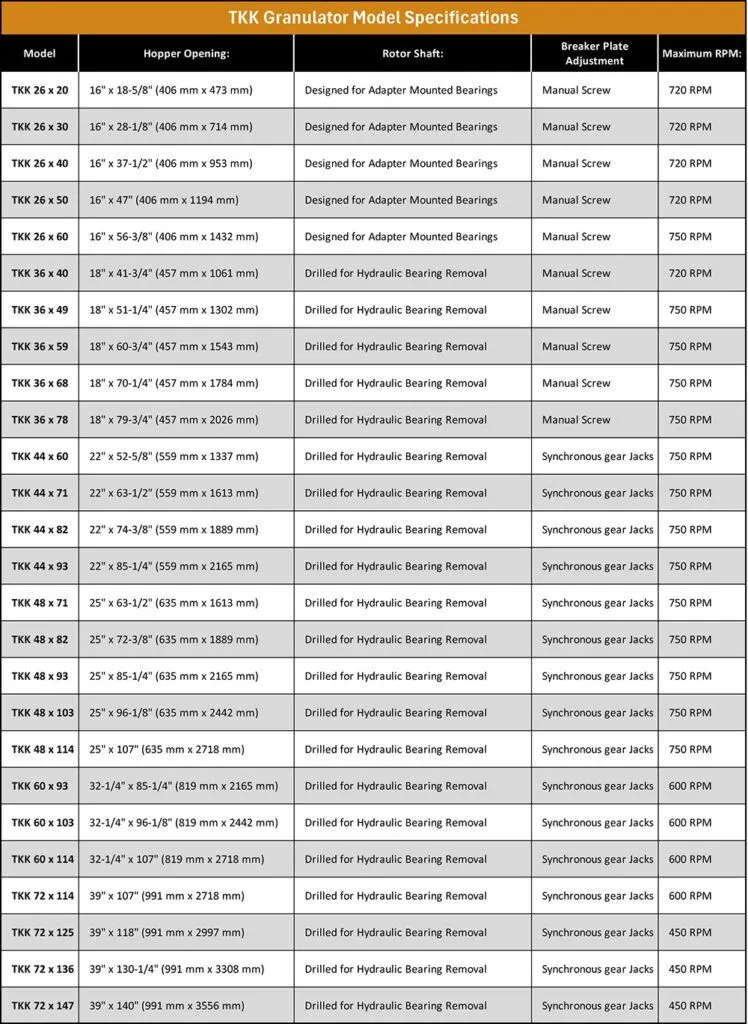

Technical Details

General Information

- Hammers: ASTM A322 Forged Steel, Reversible Ring, Tooth Type

- Frame: ASTM A36 Fabricated Steel Plate

- Frame Liners: AISI 1040/1045 Hot rolled Carbon Manganese Steel

- Breaker Plates: AISI 1040/1045 Hot rolled Carbon-Manganese Steel

- Screen Plates: AISI 1040/1045 Hot rolled Carbon-Manganese Steel

- Cage Frame: ASTM A36 Fabricated Steel Plate

- Cage Hinge Shaft: AISI 1018 Cold-Finished Steel, AISI

- Rotor Shaft: ASTM A668 Class E Forged Heat Treated Steel

- End Discs: AISI 1040/1045 Hot rolled Carbon Manganese Steel

- Suspension Arm: AISI 1040/1045 Hot rolled Carbon Manganese Steel

- Suspension Bars: AISI 4140 Steel, Heat treated for high hardness

- Bearings: Self Aligning Spherical Roller, Tapered Bore Bearings

- Bearing Housings: Cast Iron, Split with Labyrinth Seals

- Standard Lubrication is grease: however optional oil circulating systems are available

- B10 Bearing Life: 80,000 – 100,000 hours

General Information

- Hammers: ASTM A322 Forged Steel, Reversible Ring, Tooth Type

- Frame: ASTM A36 Fabricated Steel Plate

- Frame Liners: AISI 1040/1045 Hot rolled Carbon Manganese Steel

- Breaker Plates: AISI 1040/1045 Hot rolled Carbon-Manganese Steel

- Screen Plates: AISI 1040/1045 Hot rolled Carbon-Manganese Steel

- Cage Frame: ASTM A36 Fabricated Steel Plate

- Cage Hinge Shaft: AISI 1018 Cold-Finished Steel, AISI

- Rotor Shaft: ASTM A668 Class E Forged Heat Treated Steel

- End Discs: AISI 1040/1045 Hot rolled Carbon Manganese Steel

- Suspension Arm: AISI 1040/1045 Hot rolled Carbon Manganese Steel

- Suspension Bars: AISI 4140 Steel, Heat treated for high hardness

- Bearings: Self Aligning Spherical Roller, Tapered Bore Bearings

- Bearing Housings: Cast Iron, Split with Labyrinth Seals

- Standard Lubrication is grease: however optional oil circulating systems are available

- B10 Bearing Life: 80,000 – 100,000 hours