EnduraHog™ Redefines Crushing Performance with Every Configuration!

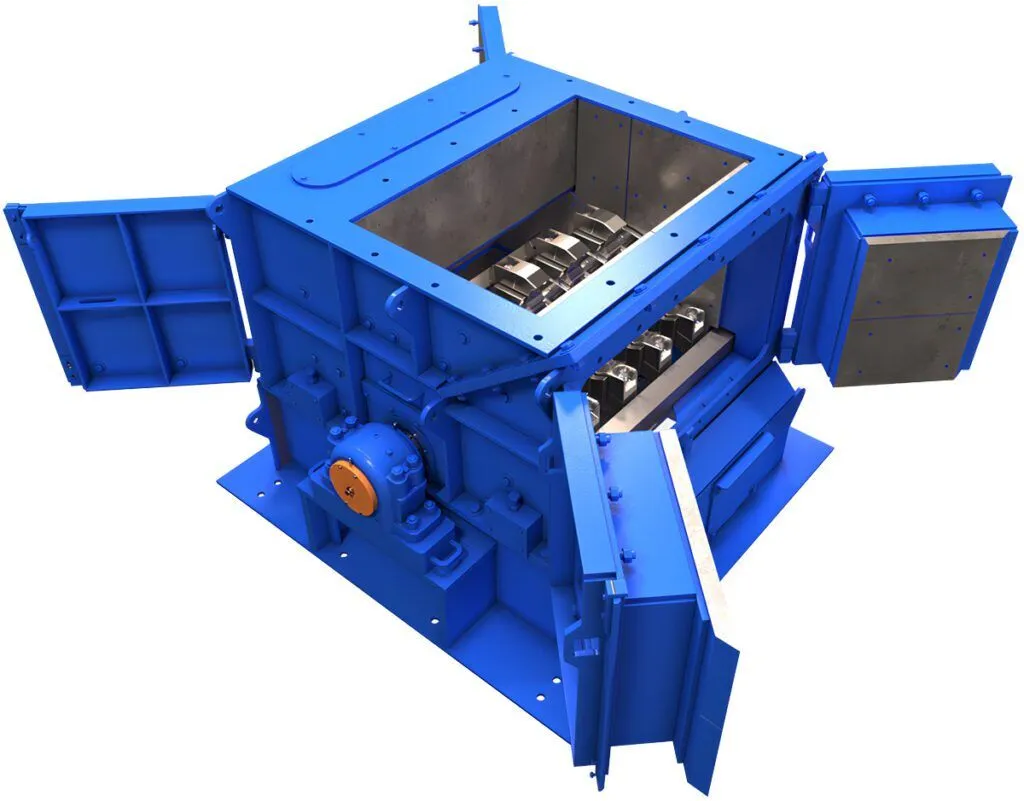

Easy-Access Panels

Remove Without Touching Chute Work

Front & Back Easy-Access

Classic

Renowned for decades, this original workhorse is celebrated as the most reliable and durable machine for precise wood and bark sizing. All have service focused enhancements.

- Agricultural/Food Processing

- Biofuels & Pellets Production

- Biomass Energy Processing

- Power Generation

- Pulp & Paper Manufacturing

- Recycling Operations

- Renewable Power Production

- Sawmill Operations

- Waste Management

- Wood Products / Furniture Mfg.

Innovative Housing Designs with Easy Access Technology:

- Unmatched accessibility to internal wear components with housing upgrades and ultra-large doors. Facilitates quick and safe maintenance, minimizing downtime and reducing the risk of injuries for maintenance operators.

- Direct outside access to front and rear breaker bars. Enables quick and convenient maintenance without the need for disassembly, further enhancing operational efficiency

- Innovative housing designs for optimal performance and durability. Enhanced durability and performance without compromising on maintenance ease, ensuring long-term reliability.

- Heavy-Duty Rotor Design:

Heavy-duty rotor design with grinder hammers. Provides rugged performance and precise sizing, along with extended usable life, reducing the frequency of replacements and maintenance costs.

Hammer Symmetric Design:

- Symmetric hammer design for extended usable life. Allows users to flip the hammer for continued use, maximizing durability and reducing replacement costs.

Wide Variety of Configurations and Hammer Sizes:

- Widest variety of configurations and hammer sizes. Ensures versatility to tackle diverse material crushing challenges effectively, meeting the specific requirements of different industries.

Complementing Hammer Design with Screen Grates

- Hammer design complementing Brute Armor™ premium screen grates. Ensures seamless integration and optimized performance of crushing parts, enhancing overall efficiency and longevity.

Chip-Sizer™

A true no-knife rechipper, Chip-Sizer™ use unique, “soft touch” semi-swing hammers to precisely fracture oversized wood chips along fiber lines.

- Agricultural/Food Processing

- Biofuels & Pellets Production

- Biomass Energy Processing

- Pulp & Paper Manufacturing

- Renewable Power Production

- Sawmill Operations

- Wood Products / Furniture Mfg.

Flextooth®

Designed for crushing hard materials in the mining and aggregates industries with specialized hammers built to offer maximum power at lower, more efficient speeds.

Cement Production

Chemical Processing

Limestone & Lime Processing

Manufactured Products Preparation

Mining Operations (Aggregate, Sand & Gravel, Coal, and Other Minerals)

Petroleum Coke Processing

Power Generation

In addition to the standard features of the Classic EnduraHog, this model includes the following specifics:

EnduraHog™ Flextooth® Features: Specialized Hammers: Tailor-made for rigorous demands, delivering unparalleled power efficiently. Minimized Fines Production: Operates at lower speeds to minimize fines generation. Uncrushable Protection: Safeguards against uncrushables with specialized hammer design. Combination Crushing: Combines roll and impact crusher strengths for high capacity and compression crushing. Patented Flextooth® Hammer Design: Flexes out of the crush zone for optimal sizing and uncrushable accommodation. Duratip® High-Alloy Hammers: Offers replaceable tips for maximum shredding and easy maintenance. Duralife Line: Part of a comprehensive line of durable parts, including Brute Armor™ screen grates and break bars. Benefits: Maximum Power: Offers maximum power at more efficient speeds. Damage Protection: Provides additional protection from uncrushables, minimizing equipment damage. Efficient Crushing: Minimizes fines production while maintaining high capacity crushing capabilities. Optimal Sizing: Ensures optimal sizing by flexing hammers and accommodating uncrushables. Easy Maintenance: Replaceable tips and durable parts simplify maintenance procedures. Long-Wear Performance: Forms part of a long-wear, high-performance OEM crushing solution. Versatile Application: Ideally designed for hard materials in mining and aggregates industries.Grinder

This “all purpose” crusher is the most versatile, used in facilities to size everything from building materials to recyclables, pharmaceutical waste, glass, biomass, plastics and more.

Cement Production

Chemical Processing

Limestone & Lime Processing

Manufactured Products Preparation

Mining Operations (Aggregate, Sand & Gravel, Coal, Gypsum, Potash, and Other Minerals)

Petroleum Coke Processing

Power Generation

Recycling Operations

Steel Production

In addition to the standard features of the Classic EnduraHog, this model includes the following specifics:

EnduraHog™ Grinders Features: Versatility: Designed for a wide range of applications, from processing building materials to recyclables, pharmaceutical waste, glass, biomass, plastics, and more. Various Sizes and Configurations: Available in multiple sizes and configurations to suit different processing needs. Durable Hammer Designs: Hammer designs prioritize precision sizing and longevity, with the ability to flip hammers for extended use. Custom Alloys: Custom alloys available for challenging applications, enhancing functionality and durability. Compatibility: Seamlessly pairs with Brute Armor™ premium screen grates and break bars for enhanced performance. Benefits: Versatile Processing: Effectively processes diverse materials, making it suitable for a wide range of facilities and applications. Longevity: Durable hammer designs and the ability to flip hammers for extended use increase the usable life of the grinder. Optimal Functionality: Custom alloys improve functionality in challenging applications, ensuring efficient processing. Enhanced Performance: Compatibility with Brute Armor™ premium screen grates and break bars ensures unmatched performance and reliability.SuperSlugger

Reigns supreme for sizing the biggest wood infeeds — from railroad ties to wooden spools to large diameter timber — the SuperSlugger & its extra heavy hammers are up to the task.

Agricultural/Food Processing

Biofuels & Pellets Production

Biomass Energy Processing

Power Generation

Pulp & Paper Manufacturing

Recycling Operations

Renewable Power Production

Sawmill Operations

Waste Management

Wood Products / Furniture Mfg.

In addition to the standard features of the Classic EnduraHog, this model includes the following specifics:

EnduraHog™ SuperSlugger Features: Extra Heavy Hammers: Designed to handle the largest wood infeeds, from railroad ties to hefty timber. Robust Rotor: Features heavier and wider hammers for efficient processing of massive infeed pieces. Duralife® Premium Hammer Design: Offers optimal crushing performance and durability. Swing Hammer Design: Minimizes damage from uncrushable materials like steel. Variety of Hammer Designs: Includes Duralife® premium options and other wear-resistant materials. Easy Maintenance: Replaceable Duratips® and quick changeout during maintenance periods. Compatibility: Complements Brute Armor™ premium screen grates and break bars for enhanced performance. Benefits: Ultimate Solution for Large Wood Infeeds: Handles challenging applications with ease. Efficient Processing: Ensures efficient processing of massive infeed pieces. Minimized Damage: Minimizes damage from uncrushable materials, improving equipment longevity. Optimal Crushing Performance: Provides optimal crushing action for high performance. Durability: Duralife® premium hammer design and robust construction ensure long-lasting performance. Easy Maintenance: Simplifies maintenance tasks, reducing downtime. High Performance OEM Parts Portfolio: Enhances overall equipment performance for any operation.Classic

Renowned for decades, this original workhorse is celebrated as the most reliable and durable machine for precise wood and bark sizing. All have service focused enhancements.

Chip-Sizer™

A true no-knife rechipper, Chip-Sizer™ use unique, “soft touch” semi-swing hammers to precisely fracture oversized wood chips along fiber lines.

Flextooth®

Designed for crushing hard materials in the mining and aggregates industries with specialized hammers built to offer maximum power at lower, more efficient speeds.

Grinder

This “all purpose” crusher is the most versatile, used in facilities to size everything from building materials to recyclables, pharmaceutical waste, glass, biomass, plastics and more.

SuperSlugger

Reigns supreme for sizing the biggest wood infeeds — from railroad ties to wooden spools to large diameter timber — the SuperSlugger & its extra heavy hammers are up to the task.

- Agricultural/Food Processing

- Biofuels & Pellets Production

- Biomass Energy Processing

- Power Generation

- Pulp & Paper Manufacturing

- Recycling Operations

- Renewable Power Production

- Sawmill Operations

- Waste Management

- Wood Products / Furniture Mfg.

Innovative Housing Designs with Easy Access Technology:

- Unmatched accessibility to internal wear components with housing upgrades and ultra-large doors. Facilitates quick and safe maintenance, minimizing downtime and reducing the risk of injuries for maintenance operators.

- Direct outside access to front and rear breaker bars. Enables quick and convenient maintenance without the need for disassembly, further enhancing operational efficiency

- Innovative housing designs for optimal performance and durability. Enhanced durability and performance without compromising on maintenance ease, ensuring long-term reliability.

- Heavy-Duty Rotor Design:

Heavy-duty rotor design with grinder hammers. Provides rugged performance and precise sizing, along with extended usable life, reducing the frequency of replacements and maintenance costs.

Hammer Symmetric Design:

- Symmetric hammer design for extended usable life. Allows users to flip the hammer for continued use, maximizing durability and reducing replacement costs.

Wide Variety of Configurations and Hammer Sizes:

- Widest variety of configurations and hammer sizes. Ensures versatility to tackle diverse material crushing challenges effectively, meeting the specific requirements of different industries.

Complementing Hammer Design with Screen Grates

- Hammer design complementing Brute Armor™ premium screen grates. Ensures seamless integration and optimized performance of crushing parts, enhancing overall efficiency and longevity.

Agricultural/Food Processing

Biofuels & Pellets Production

Biomass Energy Processing

Pulp & Paper Manufacturing

Renewable Power Production

Sawmill Operations

Wood Products / Furniture Mfg.

Cement Production

Chemical Processing

Limestone & Lime Processing

Manufactured Products Preparation

Mining Operations (Aggregate, Sand & Gravel, Coal, and Other Minerals)

Petroleum Coke Processing

Power Generation

In addition to the standard features of the Classic EnduraHog, this model includes the following specifics:

EnduraHog™ Flextooth® Features: Specialized Hammers: Tailor-made for rigorous demands, delivering unparalleled power efficiently. Minimized Fines Production: Operates at lower speeds to minimize fines generation. Uncrushable Protection: Safeguards against uncrushables with specialized hammer design. Combination Crushing: Combines roll and impact crusher strengths for high capacity and compression crushing. Patented Flextooth® Hammer Design: Flexes out of the crush zone for optimal sizing and uncrushable accommodation. Duratip® High-Alloy Hammers: Offers replaceable tips for maximum shredding and easy maintenance. Duralife Line: Part of a comprehensive line of durable parts, including Brute Armor™ screen grates and break bars. Benefits: Maximum Power: Offers maximum power at more efficient speeds. Damage Protection: Provides additional protection from uncrushables, minimizing equipment damage. Efficient Crushing: Minimizes fines production while maintaining high capacity crushing capabilities. Optimal Sizing: Ensures optimal sizing by flexing hammers and accommodating uncrushables. Easy Maintenance: Replaceable tips and durable parts simplify maintenance procedures. Long-Wear Performance: Forms part of a long-wear, high-performance OEM crushing solution. Versatile Application: Ideally designed for hard materials in mining and aggregates industries.Cement Production

Chemical Processing

Limestone & Lime Processing

Manufactured Products Preparation

Mining Operations (Aggregate, Sand & Gravel, Coal, Gypsum, Potash, and Other Minerals)

Petroleum Coke Processing

Power Generation

Recycling Operations

Steel Production

In addition to the standard features of the Classic EnduraHog, this model includes the following specifics:

EnduraHog™ Grinders Features: Versatility: Designed for a wide range of applications, from processing building materials to recyclables, pharmaceutical waste, glass, biomass, plastics, and more. Various Sizes and Configurations: Available in multiple sizes and configurations to suit different processing needs. Durable Hammer Designs: Hammer designs prioritize precision sizing and longevity, with the ability to flip hammers for extended use. Custom Alloys: Custom alloys available for challenging applications, enhancing functionality and durability. Compatibility: Seamlessly pairs with Brute Armor™ premium screen grates and break bars for enhanced performance. Benefits: Versatile Processing: Effectively processes diverse materials, making it suitable for a wide range of facilities and applications. Longevity: Durable hammer designs and the ability to flip hammers for extended use increase the usable life of the grinder. Optimal Functionality: Custom alloys improve functionality in challenging applications, ensuring efficient processing. Enhanced Performance: Compatibility with Brute Armor™ premium screen grates and break bars ensures unmatched performance and reliability.Agricultural/Food Processing

Biofuels & Pellets Production

Biomass Energy Processing

Power Generation

Pulp & Paper Manufacturing

Recycling Operations

Renewable Power Production

Sawmill Operations

Waste Management

Wood Products / Furniture Mfg.

In addition to the standard features of the Classic EnduraHog, this model includes the following specifics:

EnduraHog™ SuperSlugger Features: Extra Heavy Hammers: Designed to handle the largest wood infeeds, from railroad ties to hefty timber. Robust Rotor: Features heavier and wider hammers for efficient processing of massive infeed pieces. Duralife® Premium Hammer Design: Offers optimal crushing performance and durability. Swing Hammer Design: Minimizes damage from uncrushable materials like steel. Variety of Hammer Designs: Includes Duralife® premium options and other wear-resistant materials. Easy Maintenance: Replaceable Duratips® and quick changeout during maintenance periods. Compatibility: Complements Brute Armor™ premium screen grates and break bars for enhanced performance. Benefits: Ultimate Solution for Large Wood Infeeds: Handles challenging applications with ease. Efficient Processing: Ensures efficient processing of massive infeed pieces. Minimized Damage: Minimizes damage from uncrushable materials, improving equipment longevity. Optimal Crushing Performance: Provides optimal crushing action for high performance. Durability: Duralife® premium hammer design and robust construction ensure long-lasting performance. Easy Maintenance: Simplifies maintenance tasks, reducing downtime. High Performance OEM Parts Portfolio: Enhances overall equipment performance for any operation.Brute Armor™ Slant-Flow®

Discover why Slant-Flow® Screen Grates reign as the premier choice for industrial operations. Engineered with superior resilience, these grates outperform brittle bi-metal parts, offering up to 4x longer wear than competitors. With precision OEM design, they ensure optimal impact-zone performance tailored to your needs.

TerraSource Global’s Jeffrey Rader line delivers unrivaled productivity, durability, and value, supported by a swift 4–8-week lead time for replacements. Embrace the Brute Armor™ premium line for maximum tramp-metal resistance and extended uptime. Benefit from enhanced shredding action, reduced clogging, and minimal operational failure, all backed by warranties on workmanship. Opt for Slant-Flow® Screen Grates and elevate your efficiency with TerraSource Global’s trusted solutions.

Slant-Flow® grates

- 180° design increases capacity and diminishes recirculating loads

- Abrasion-resistant and angled with the flow of material

- Faster evacuation

- Greater shredding action

- Less wear on grates and hammers

- Reduced clogging

- More uniform product

Technical Details

Built to last

- Rigid, welded, all-steel housing handles tough applications

- Fully-lined interior reduces housing wear

- Integral metal trap protects critical parts from damage from uncrushables

Liners

- Hardened/heat-treated materials guard against wear and heavy impact

- External fastenings prevent broken bolt heads and falling liners