Air Density Separator (ADS)

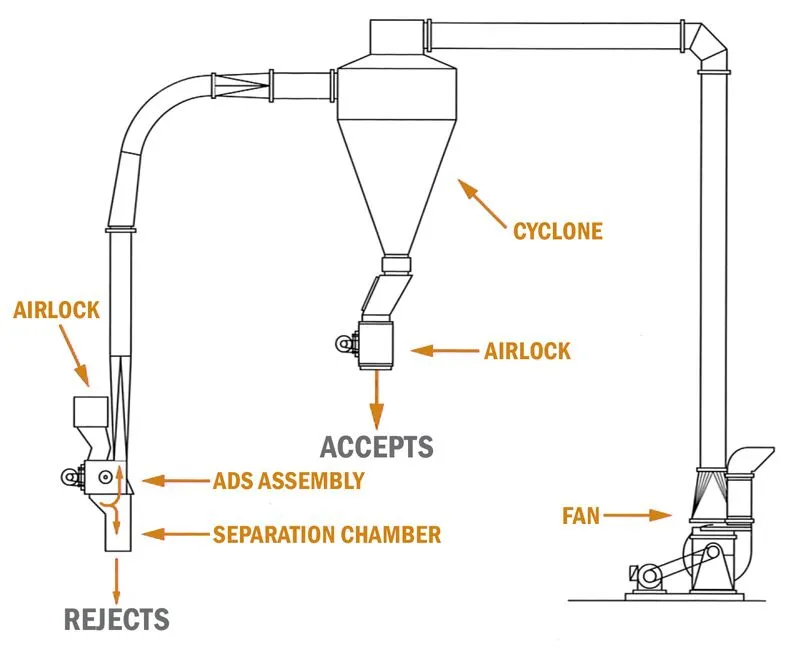

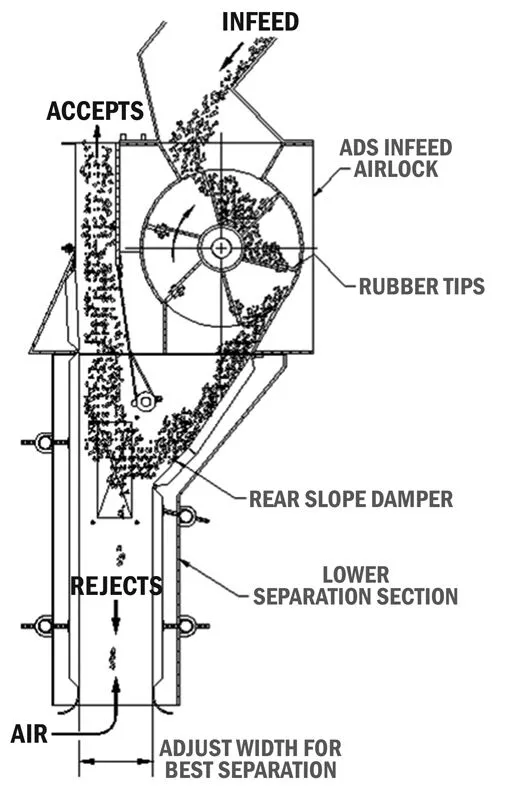

Jeffrey Rader’s Air Density Separators (ADS) are engineered for optimal efficiency and versatility, safeguarding chip conditioners, slicers, and pulp mill equipment. Featuring a unique control system, ADS creates a controlled separation zone using air curtains to efficiently remove rocks, knots, and debris while directing accepts to a cyclone, enhancing pulping and reducing rejects. Customizable to specific process needs, ADS minimizes energy use, offers equipment placement flexibility, and is ideal for wood handling, pulp and paper, and refuse/resource recovery industries, ensuring efficient separation for diverse applications.

Features/Advantages

- Pioneering Technology: Jeffrey Rader is a leader in chip processing technology, with over 40 years of experience.

- Vacuum Air System: Utilizes vacuum air systems to effectively remove chip contaminants like rocks, knots, and metal.

- Optimal Removal Efficiency: Uniquely-designed control system ensures optimal removal efficiency for chip contaminants.

- Versatility: The ADS system offers flexibility in locating chip conditioners and Chip-Sizer™ rechippers, saving space and reducing capital investment.

- Adjustable Separation Chamber: The system’s design allows for a curtain of air to be pulled across an adjustable separation chamber, facilitating efficient separation of unwanted debris from the material flow.

- Downstream Equipment Protection: Protects downstream equipment by removing rocks, knots, and compressed wood from the material flow.

- Improved Pulping Process: Enhances the pulping process by removing knots and compressed wood, leading to a reduction in pulping rejects.

- Custom Tailored Solutions: Each ADS system is custom-tailored to accommodate specific process requirements, resulting in optimized energy consumption and operational efficiency.

Industries

Biofuels & Pellets Production

Biomass Energy Processing

Pulp & Paper Manufacturing

Recycling Operations

Renewable Power Production

Sawmill Operations

Wood Products / Furniture

Manufacturing

Biofuels & Pellets Production • Biomass Energy Processing • Pulp & Paper Manufacturing • Recycling Operations

Renewable Power Production • Sawmill Operations • Wood Products / Furniture • Manufacturing