Bradford Breakers

Bradford Breakers by Pennsylvania Crusher Brand are renowned since 1905 for their precision, rugged design, and dependability in crushing, sizing, and cleaning run-of-mine coal and other friable materials worldwide. These breakers offer simultaneous sizing and cleaning, with sized coal exiting quickly through screen plate holes while unsized coal continues through the crushing chamber.

Their gravity impact mechanism minimizes fines production, while internal deflectors ensure efficient material flow for cleaning. With maximum cylinder strength and rigidity, low maintenance requirements, and comprehensive support services including installation supervision and parts supply, Bradford Breakers deliver reliable operation and long-term value.

Mining Operations (Coal)

Power Generation

Steel Production

Simultaneous Sizing and Cleaning: The Bradford Breakers perform sizing and cleaning of run-of-mine coal and other materials simultaneously.

Low Maintenance Costs: Maintenance requirements are minimal, primarily needing periodic lubrication and inspection, leading to low operational costs.

Rugged Design: The breakers have a robust design that minimizes downtime, eliminating the need for backup machines.

Reliability: Bradford Breakers have been widely used for decades and are known for their reliable performance in mines and coal preparation plants.

Comprehensive Support Services: Pennsylvania Crusher offers installation supervision, training, responsive parts, and service support, ensuring continuous operation and minimal downtime.

Design Advantages: The breakers feature maximum cylinder strength and rigidity, T-beams for rigidity and corrosion resistance, and precise fabrication of screen plates for easy maintenance and retrofitting.

Efficient Cleaning Mechanism: Internal deflectors and lifting shelves induce material flow for efficient cleaning, minimizing the production of fines.

Self-Cleaning Sizing Holes: The breakers offer several shapes of sizing holes, including a self-cleaning design that reduces plugging issues.

General Information

Spiders: ASTM A36 Fabricated Steel Plate

Longitudinal Beams: ASTM A36 Structure Steel Beam

Screen Plates: AISI 1040 Hot rolled Carbon Manganese Steel

Lifting Shelves: ASTM A36 Fabricated Steel Plate

Deflectors: ASTM A36 Fabricated Steel Plate

Refuse Plow: ASTM A36 Fabricated Steel Plate

Cylinder Tires: ASTM A551 Class DHT Heat Treated Steel

Wheel: ASTM A504 Class C Heat Treated Steel

Wheel Shaft Bearing Standard Lubrication is grease

B10 Bearing Life: > 100,000 hours

Bradford Breaker RMD 9 x 12 Specifications

Effective Diameter: 8’ – 6″ (2591 mm)

Effective Screen Plates Length: 12’ – 0” (3658 mm)

Cylinder Speed: 13 RPM (Nominal)

Maximum HP/RPM: 40 HP/1800 RPM

Bradford Breaker RMD 9 x 16 Specifications

Effective Diameter: 8’ – 6″ (2591 mm)

Effective Screen Plates Length: 16’ – 0” (4877 mm)

Cylinder Speed: 13 RPM (Nominal)

Maximum HP/RPM: 50 HP/1800 RPM

Bradford Breaker RMD 9 x 20 Specifications

Effective Diameter: 8’ – 6″ (2591 mm)

Effective Screen Plates Length: 20’ – 0” (6096 mm)

Cylinder Speed: 13 RPM (Nominal)

Maximum HP/RPM: 60 HP/1800 RPM

Bradford Breaker RMD 9 x 24 Specifications

Effective Diameter: 8’ – 6″ (2591 mm)

Effective Screen Plates Length: 24’ – 0” (7315 mm)

Cylinder Speed: 13 RPM (Nominal)

Maximum HP/RPM: 75 HP/1800 RPM

Bradford Breaker RMD 12 x 16 Specifications

Effective Diameter: 10’ – 10″ (3302 mm)

Effective Screen Plates Length: 16’ – 0” (4877 mm)

Cylinder Speed: 11 RPM (Nominal)

Maximum HP/RPM: 75 HP/1800 RPM

Bradford Breaker RMD 12 x 20 Specifications

Effective Diameter: 10’ – 10″ (3302 mm)

Effective Screen Plates Length: 20’ – 0” (6096 mm)

Cylinder Speed: 11 RPM (Nominal)

Maximum HP/RPM: 100 HP/1800 RPM

Bradford Breaker RMD 12 x 24 Specifications

Effective Diameter: 10’ – 10″ (3302 mm)

Effective Screen Plates Length: 24’ – 0” (7315 mm)

Cylinder Speed: 11 RPM (Nominal)

Maximum HP/RPM: 125 HP/1800 RPM

Bradford Breaker RMD 12 x 28 Specifications

Effective Diameter: 10’ – 10″ (3302 mm)

Effective Screen Plates Length: 28’ – 0” (8534 mm)

Cylinder Speed: 11 RPM (Nominal)

Maximum HP/RPM: 150 HP/1800 RPM

Bradford Breaker RMD 14 x 20 Specifications

Effective Diameter: 13’ – 1 ½” (4001 mm)

Effective Screen Plates Length: 20’ – 0” (6096 mm)

Cylinder Speed: 10 RPM (Nominal)

Maximum HP/RPM: 150 HP/1800 RPM

Bradford Breaker RMD 14 x 24 Specifications

Effective Diameter: 13’ – 1 ½” (4001 mm)

Effective Screen Plates Length: 24’ – 0” (7315 mm)

Cylinder Speed: 10 RPM (Nominal)

Maximum HP/RPM: 200 HP/1800 RPM

Bradford Breaker RMD 14 x 28 Specifications

Effective Diameter: 13’ – 1 ½” (4001 mm)

Effective Screen Plates Length: 28’ – 0” (8534 mm)

Cylinder Speed: 10 RPM (Nominal)

Maximum HP/RPM: 250 HP/1800 RPM

Bradford Breaker RMD 14 x 32 Specifications

Effective Diameter: 13’ – 1 ½” (4001 mm)

Effective Screen Plates Length: 32’ – 0” (9754 mm)

Cylinder Speed: 10 RPM (Nominal)

Maximum HP/RPM: 250 HP/1800 RPM

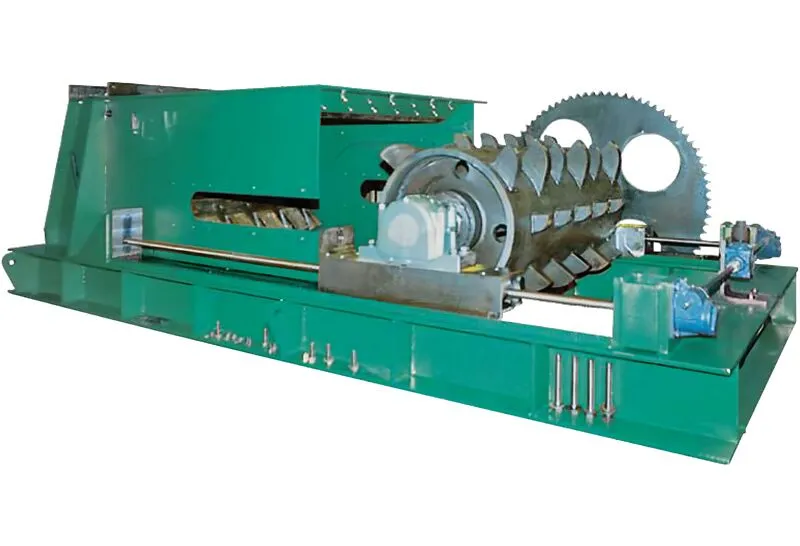

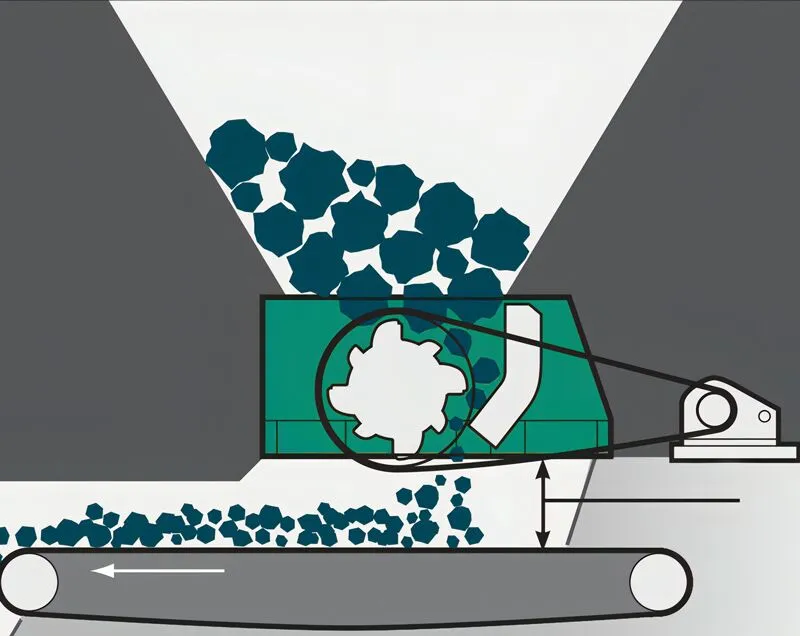

Frozen Coal Cracker

The Frozen Coal Cracker offers a solution to unloading challenges in rotary car dump operations, where large frozen lumps can lead to serious jams and damage. This innovative system quickly reduces frozen coal chunks, facilitating faster unloading, minimizing damage, and reducing downtime and labor requirements.

Its low-profile design and wide feed opening ensure efficient operation, quicker unloading, reduced demurrage charges, elimination of damage and jams, and simplified changeovers between warm and cold weather operations. Equipped with a spring-loaded toggle mechanism for damage protection, this solution ensures smooth operation even in challenging conditions, making it indispensable for coal handling in cold weather areas worldwide.

Mining Operations (Coal)

Power Generation

Steel Production

Features:

Quick Size Reduction for Frozen Coal Chunks

Low Profile Design fits under Rotary Car Dump Stations or Reclaim Hoppers

Wide Feed Opening Prevents Jam-ups

Complete Reduction to Minus 6″ to 8″ Output Size

Spring-Loaded Toggle Mechanism for Damage Protection

External Adjustability for Product Size Control and Wear Compensation

Flexibility in Positioning with Separate Drive Assembly

Slip Type Coupling for Motor Protection

Benefits:

Faster Unloading Reduces Demurrage Charges

Damage Elimination Improves Operational Efficiency

Jam Prevention Ensures Smoother Operation

Reduced Equipment Costs and Maintenance

Decreased Downtime Enhances Productivity

Labor Savings Optimizes Manpower Resources

Simplified Changeovers Enhance Operational Efficiency

Global Applicability in Cold Weather Areas

General Information

There are two models available: FCC and FCCR.

Capacities shown are based on reducing precrushed coal weighing 50 lbs./cu. ft. (801 kg/cu. m.) that has frozen into agglomerated clumps to a nominal 6″ (152 mm) output size. For other output sizes, consult us for capacity information.

30″ x 40″

Capacity: 625 TPH

HP: 60

30″ x 50″

Capacity: 750 TPH

HP: 75

30″ x 60″

Capacity: 1000 TPH

HP: 100

30″ x 72″

Capacity: 1250 TPH

HP: 125

30″ x 84″

Capacity: 1500 TPH

HP: 150

30″ x 100″

Capacity: 1800 TPH

HP: 150

30″ x 120″

Capacity: 2100 TPH

HP: 200

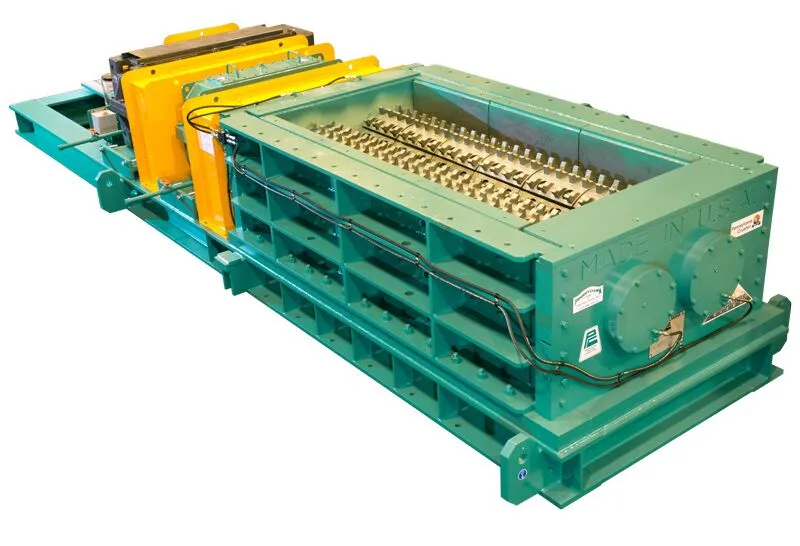

Mountaineer® II Sizers

Mountaineer® II Sizers are designed for primary or secondary sizing of coals, industrial minerals, and ores while minimizing fines. These robust Sizers feature a modular design with off-the-shelf standard parts and a separate link gear box for enhanced performance and easy maintenance.

They come with advanced tramp metal protection, optional torque limiters, and electronic torque limiting devices. The Sizers are built for quick component changeout, reducing downtime and maintenance costs. With a focus on durability and reliability, they offer high-capacity operation with low headroom and structural requirements. From rapid rotor replacement to efficient crushing teeth replacement, these Sizers ensure optimal results for critical sizing tasks.

Cement Production

Mining Operations

(Aggregate, Sand & Gravel, Coal, Potash, and Other Minerals)

Recycling Operations

Steel Production

Features:

Modular Design with Uni-frame Construction

Off-the-shelf Standard Parts

Separate Link Gear Box (LGB)

Tougher Design with More Tramp Metal Protection Technology

Optional Torque Limiters and Electronic Torque Limiting Devices

Quick Changeout of Components with Modular Construction

Independent Link Gear Box (LGB) for increased durability

Crushing Teeth easily replaced in under one hour

Benefits:

Increased uptime and minimized maintenance costs with quick component changeout

Rapid replacement of components, aligning, and back in production in 8 hours or less

Simplified design eliminates the need for special maintenance skills

Reduced repair time with easily changeable Independent Link Gear Box (LGB)

Factory warranty rebuild exchange program for LGB and rotors, ensuring support and reliability

Quick and easy replacement of crushing teeth, minimizing downtime

Enhanced durability and reliability, minimizing downtime for repairs

Protection against tramp metal, prolonging equipment lifespan

Versatile torque limiting options for operational flexibility

General Information

Frame: ASTM A36 Fabricated Steel Plate

Frame Liners: AISI 1040/1045 Hot rolled Carbon Manganese Steel

Breaker Plates: AISI 1040/1045 Hot rolled Carbon-Manganese Steel or AR400F Fabricated Steel

Rotor Teeth: High Silicon Alloy Cast Steel

Rotor Hub: ASTM A36 Fabricated Steel Plate

Rotor Shaft: ASTM A668 Class K (AISI 4340) Forged Heat Treated Steel

Bearings: Self Aligning Spherical Roller, Cylindrical Bore Bearings

Bearing Housings: A36 Carbon Steel, Tubular, Capped with Labyrinth Seals

Standard Lubrication is grease

B10 Drive Rotor Life: 60,000 hours

Drive Base: Structural Wide Flange

SR 5025 Sizer Specification

Hopper Opening: 75″ x 47″ (1905 mm x 1194 mm)

SR 5030 Sizer Specification

Hopper Opening: 90″ x 47″ (2286 mm x 1194 mm)

SR 6520 Sizer Specification

Hopper Opening: 80″ x 64″ (2032 mm x 1626 mm)

SR 6530 Sizer Specification

Hopper Opening: 120″ x 64″ (3048 mm x 1626 mm)

SR 8020 Sizer Specification

Hopper Opening: 90″ x 71″ (2286 mm x 1803 mm)

SR 8030 Sizer Specification

Hopper Opening: 135″ x 71″ (3429 mm x 1803 mm)

SR 10020 Sizer Specification

Hopper Opening: 90″ x 91 ½” (2286 mm x 2324 mm)

SR 10030 Sizer Specification

Hopper Opening: 135″ x 91 ½” (3429 mm x 2324 mm)

Bradford Breakers Wheel Mount

Frozen Coal Cracker Installation