NANOSIZ-R and NANOSIZ-R HC

NANOSIZ-R HC by Gundlach Crushers are ideal for fine-grinding applications of limestone, fertilizers (including nitrate, phosphate, and potash), and other friable materials. The NANOSIZ-R HC roll mill delivers crushing performance that provides a real edge in day-to-day operations. It’s compact, affordable, and perfect for making 1 to 2 mm (.04″ to .08″) product, generating less dust and noise compared to other crushers. The standard version can crush up to 40 short tons per hour, while the high-capacity version can handle up to 132 short tons per hour. With various roll groove configurations, durable construction, and versatile design, these roll mills offer efficient, cost-effective, and precise crushing capabilities for a range of materials.

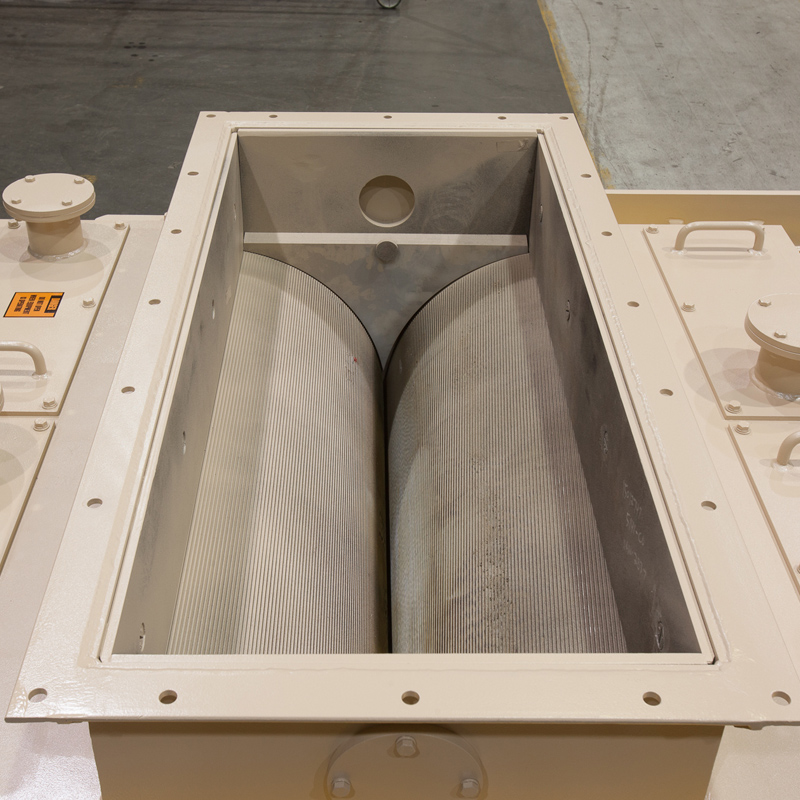

Inlet View of Corrugated Rolls

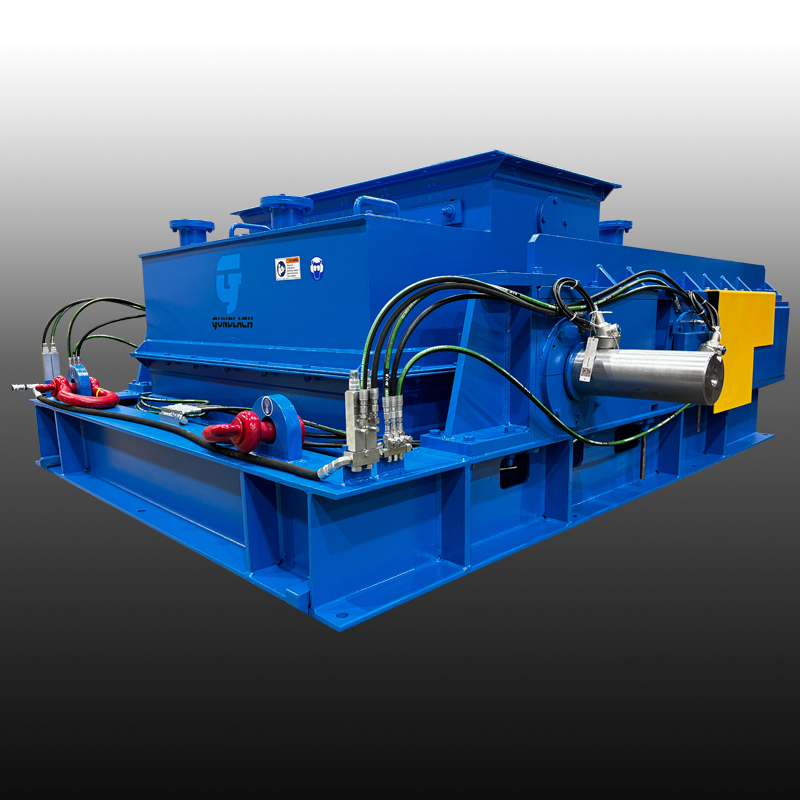

High Capacity Model

Close-Up of Corrugated Rolls

Features and Benefits

- Compact and affordable design.

- Available in standard and high-capacity models.

- Less dust generation and low noise compared to similar crushers.

- Grooved (corrugated) rolls for consistent fine product output.

- Various roll groove configurations available to suit different applications.

- Rolls can be re-grooved for extended use.

- Close-clearance double-row spherical roller bearings for tight product size control.

- Special combination shaft/housing seals and ventilation ports for efficient airflow management.

- Available in different roll lengths to meet capacity requirements.

- Real edge in day-to-day operations with high crushing performance.

- Crushes up to 40 short tons per hour (standard) or 132 short tons per hour (high-capacity).

- Suitable for fine-grinding applications of limestone, fertilizers, and other friable materials.

- Lower capital and energy costs compared to existing technologies.

- Small footprint for installation in limited spaces.

- Versatility for processing salts and fertilizers with different material characteristics.

- Reliable roll mill technology with proven performance in fine-grinding applications.

- High service reliability with reported online service of 98%.

- Heavy-duty construction for durability and long-lasting performance.

- Accurate roll gap adjustment system for precise control over product size.

- Adjustable side and end liners for optimal fit and performance.

- Flanged input and discharge connections for easy integration into processing lines.

Features and Benefits

- Compact and affordable design.

- Available in standard and high-capacity models.

- Less dust generation and low noise compared to similar crushers.

- Grooved (corrugated) rolls for consistent fine product output.

- Various roll groove configurations available to suit different applications.

- Rolls can be re-grooved for extended use.

- Close-clearance double-row spherical roller bearings for tight product size control.

- Special combination shaft/housing seals and ventilation ports for efficient airflow management.

- Available in different roll lengths to meet capacity requirements.

- Real edge in day-to-day operations with high crushing performance.

- Crushes up to 40 short tons per hour (standard) or 132 short tons per hour (high-capacity).

- Suitable for fine-grinding applications of limestone, fertilizers, and other friable materials.

- Lower capital and energy costs compared to existing technologies.

- Small footprint for installation in limited spaces.

- Versatility for processing salts and fertilizers with different material characteristics.

- Reliable roll mill technology with proven performance in fine-grinding applications.

- High service reliability with reported online service of 98%.

- Heavy-duty construction for durability and long-lasting performance.

- Accurate roll gap adjustment system for precise control over product size.

- Adjustable side and end liners for optimal fit and performance.

- Flanged input and discharge connections for easy integration into processing lines.

Industries

Cement Production • Chemical Processing • Limestone & Lime Processing • Mining Operations (Coal, Potash, and Other Minerals)

Petroleum Coke Processing • Power Generation. • Steel Production

Technical Details

- 18″ diameter rolls (standard model) and 32″ diameter rolls (high-capacity model) are constructed of a chilled iron alloy for high surface hardness.

- Rolls are grooved (corrugated) to produce a consistently fine product.

- A variety of roll groove configurations, including LePage and LePage Ring, are available on the standard model to suit various applications.

- Multiple configurations are available on the high-capacity model as well to meet your specific applications or crushing needs.

- With proper care, rolls can be re-grooved to extend their useful life.

- Close-clearance double-row spherical roller bearings are used to help maintain tight product size.

- Shaft material: 4140 steel, Forged.

- Special combination shaft/housing seals and ventilation ports facilitate system airflow management.

- Standard model NANOSIZ-R® roll mills are available with roll lengths of 508 mm (20″), 1016 mm (40″), and 1524 mm (60″) to suit a wide variety of capacity requirements. High-capacity model is available with a 1524mm (60″) roll length.

- 18″ diameter rolls (standard model) and 32″ diameter rolls (high-capacity model) are constructed of a chilled iron alloy for high surface hardness.

- Rolls are grooved (corrugated) to produce a consistently fine product.

- A variety of roll groove configurations, including LePage and LePage Ring, are available on the standard model to suit various applications.

- Multiple configurations are available on the high-capacity model as well to meet your specific applications or crushing needs.

- With proper care, rolls can be re-grooved to extend their useful life.

- Close-clearance double-row spherical roller bearings are used to help maintain tight product size.

- Shaft material: 4140 steel, Forged.

- Special combination shaft/housing seals and ventilation ports facilitate system airflow management.

- Standard model NANOSIZ-R® roll mills are available with roll lengths of 508 mm (20″), 1016 mm (40″), and 1524 mm (60″) to suit a wide variety of capacity requirements. High-capacity model is available with a 1524mm (60″) roll length.